Rising stem forged steel gate valve

Size: 1/2" to 2"

Pressure Rating: up to 138 bar

Material:Forged Steel A105N body and bonnet

Design Standard: API602, BS5352, ASME B16.34

Inspection Standard:API598

Application medium: throttle steam, gas or liquids

Send E-mail:info@wsdvalve.com Mobile: +86-173197327665

A forged steel gate valve is a type of valve that is used to regulate the flow of fluids or gases in pipelines. The valve is made of forged steel, which is a type of steel that has been formed by heating and hammering. This process creates a stronger and more durable material than cast steel.

The gate valve has a gate or disc that moves up and down to control fluid or gas flow through the valve. When the gate is lifted, the valve is open, allowing fluid or gas to flow through the pipeline. When the gate is lowered, the valve is closed, stopping fluid or gas flow.

Forged steel gate valves are typically used in high-pressure and high-temperature applications, such as oil and gas. They are also commonly used in steam applications, as well as in power plants and chemical plants. These valves are known for their reliability, durability, and ability to handle a wide range of fluids and gases.

This class 800 Forged carbon steel Gate Valve for heavy-duty use is appropriate for the most challenging process apps. When the media goes through it, the minimum quantity of turbulence will flow, and the pressure drop is very low. That’s why this gate valve is used in sectors where viscous fluid and fluid separation is needed.

Why choose us!

-

WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards

for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

W -

The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

E -

Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

S -

One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

D -

WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

O -

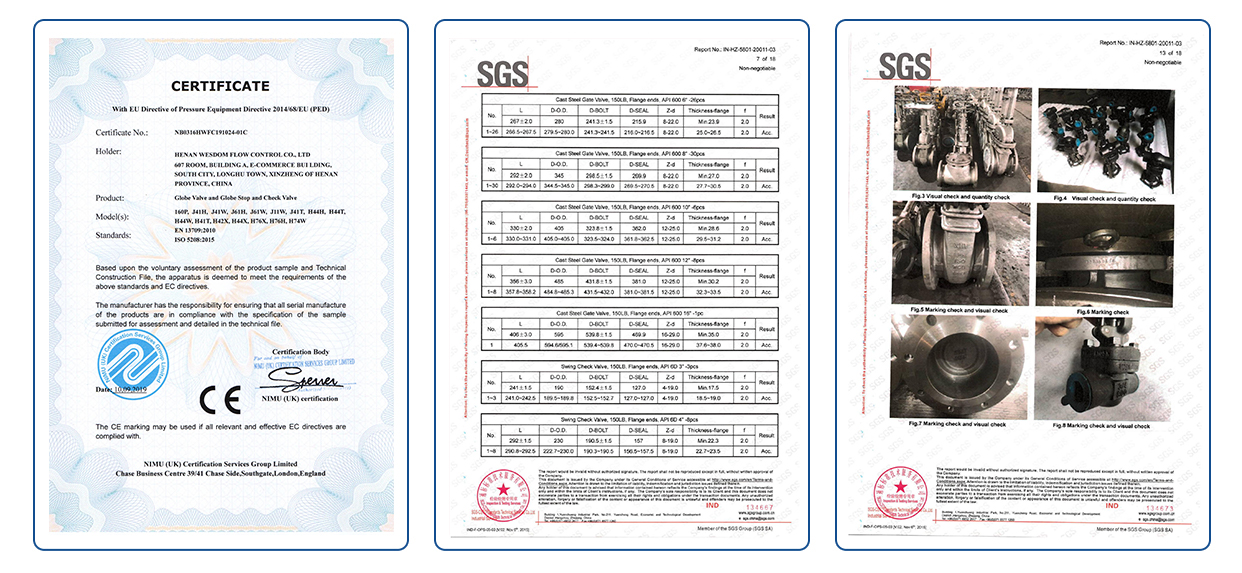

WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

M

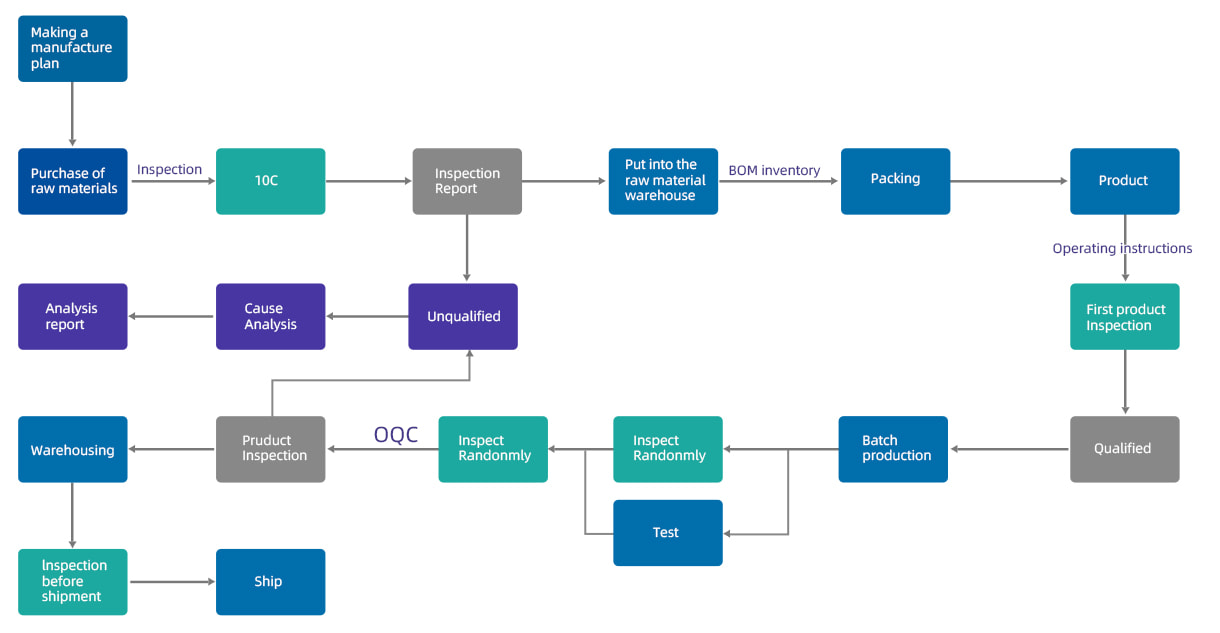

Quality Control Process

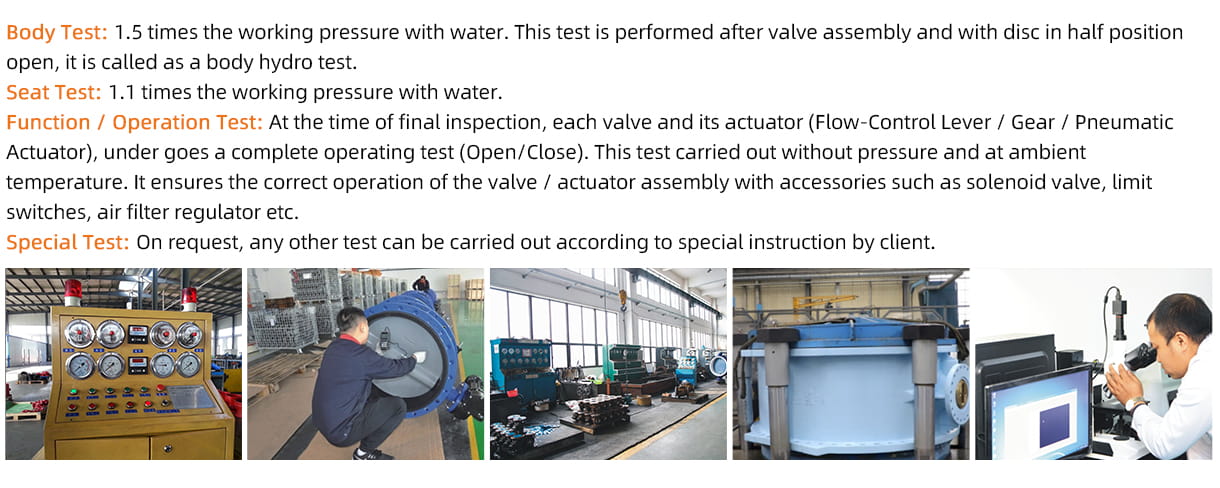

Standard Test

Factory Tour

WEIZIDOM GROUP consists of 5 factories and 4 overseas branches. The five factories are mainly located in Tianjin, Hebei, Shandong, Lianyungang

and Wenzhou. The four foreign branches are located in Tanzania, Zambia, Kenya and Indonesia.

|

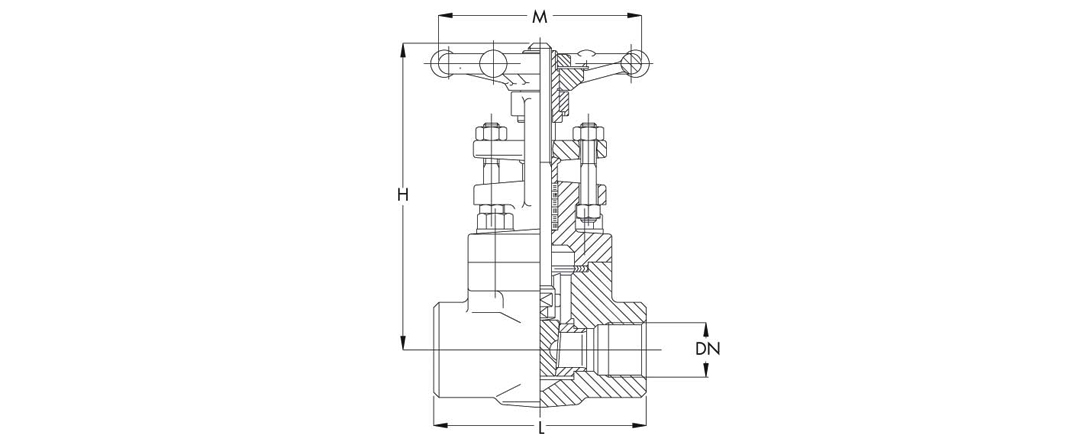

DN(Inch) |

PN(LBS) |

Connection |

L |

H (open) |

M |

Weight (kg) |

|

1/2″ |

800 lbs |

FF threaded, NPT |

83 |

160 |

102 |

1,7 |

|

3/4″ |

800 lbs |

FF threaded, NPT |

89 |

165 |

102 |

2 |

|

1″ |

800 lbs |

FF threaded, NPT |

98 |

184 |

102 |

2,8 |

|

1 1/2″ |

800 lbs |

FF threaded, NPT |

121 |

232 |

140 |

5,4 |

|

2″ |

800 lbs |

FF threaded, NPT |

140 |

281 |

168 |

9,3 |

Advantages of forged steel gate valve!

-

Durability

Forged steel gate valves are extremely durable and can withstand high temperatures and pressures. They are less prone to wear and tear than other valves, making them ideal for use in harsh environments.

W -

Corrosion Resistance

Forged steel gate valves are highly resistant to corrosion, making them ideal for use in pipelines that carry corrosive fluids or gases.

E -

Tight Seal

The gate of a forged steel gate valve is designed to fit tightly against the valve seat, providing a tight seal that prevents leakage and ensures efficient flow control.

S -

High Flow Capacity

Forged steel gate valves have a larger flow capacity than other valves, making them ideal for use in applications with high flow rates.

D -

Low-Pressure Drop

The design of forged steel gate valves ensures minimal pressure drop across the valve, which helps to minimize energy losses and ensure efficient flow control.

O -

Easy Maintenance

Forged steel gate valves are relatively easy to maintain and repair, which helps to reduce downtime and maintenance costs.

M

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.