BS resilient seated gate valve

Diameter: DN40-600

Pressure: PN1.0 / 1.6mpa

Pressure test: BS5163/ISO5208

Temperature: 0-80 ℃

Medium: Water, gas etc.

Send E-mail:info@wsdvalve.com Mobile: +86-173197327665

BS resilient seated gate valve is a new type of valve equipment. It is characterized by the use of soft materials such as rubber rings between wedge discs and seats to achieve sealing. Compared with the traditional hard and dense sealing valve, the sealing and performance have obtained a lot promote. The soft sealing gate valve provides a tightening force through high quality spring and pressure plates so as to achieve a better sealing effect. It can adapt to different working environments and needs. The soft sealing gate valve has the advantages of sealing reliability, long service life, and energy saving and consumption reduction. It is widely used in the fields of power stations, pharmaceuticals, chemicals, and sewage treatment. Due to the sealing ring of the soft sealing gate valve being made of highly elastic materials, it has a long service life, and it is also helpful to reduce maintenance costs.

Why choose us!

-

WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards

for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

W -

The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

E -

Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

S -

One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

D -

WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

O -

WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

M

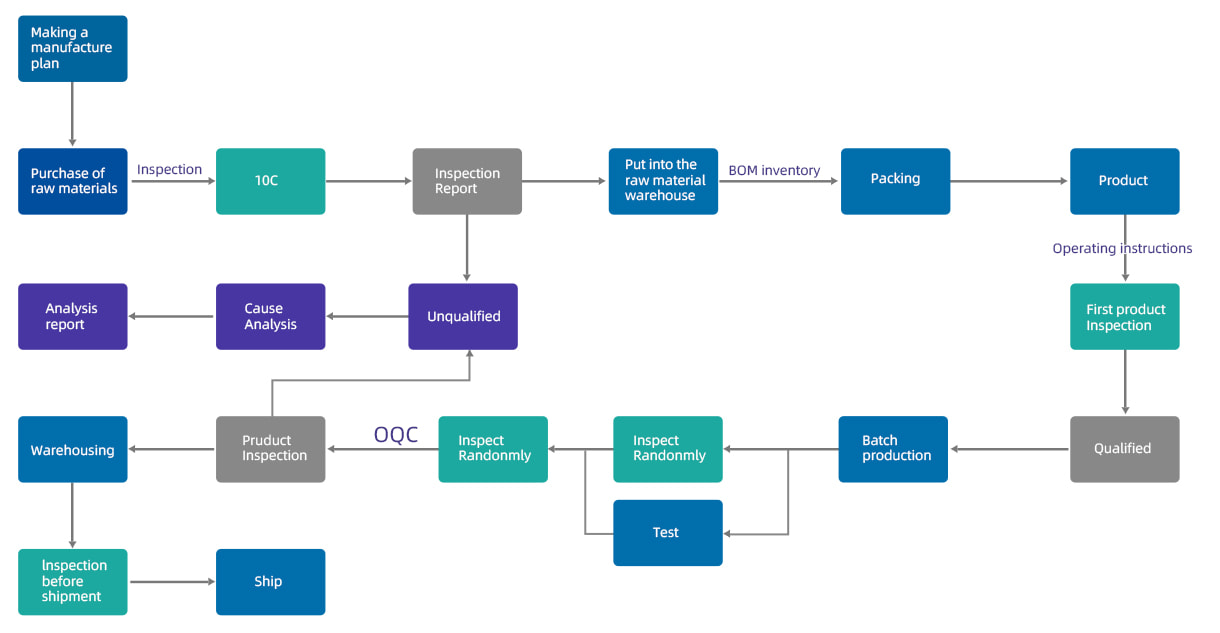

Quality Control Process

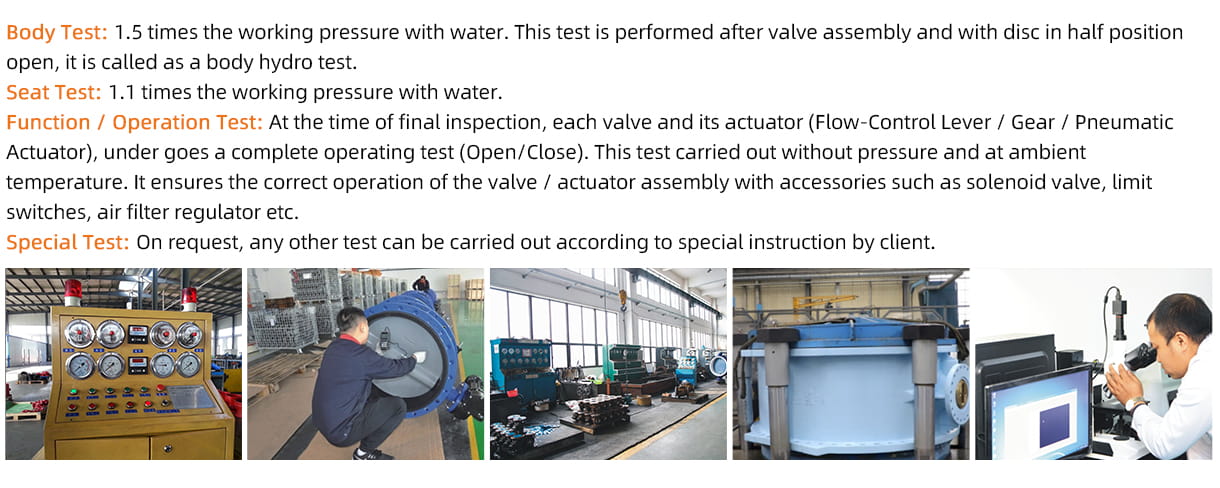

Standard Test

Factory Tour

WEIZIDOM GROUP consists of 5 factories and 4 overseas branches. The five factories are mainly located in Tianjin, Hebei, Shandong, Lianyungang and Wenzhou. The four foreign branches are located in Tanzania, Zambia, Kenya and Indonesia.

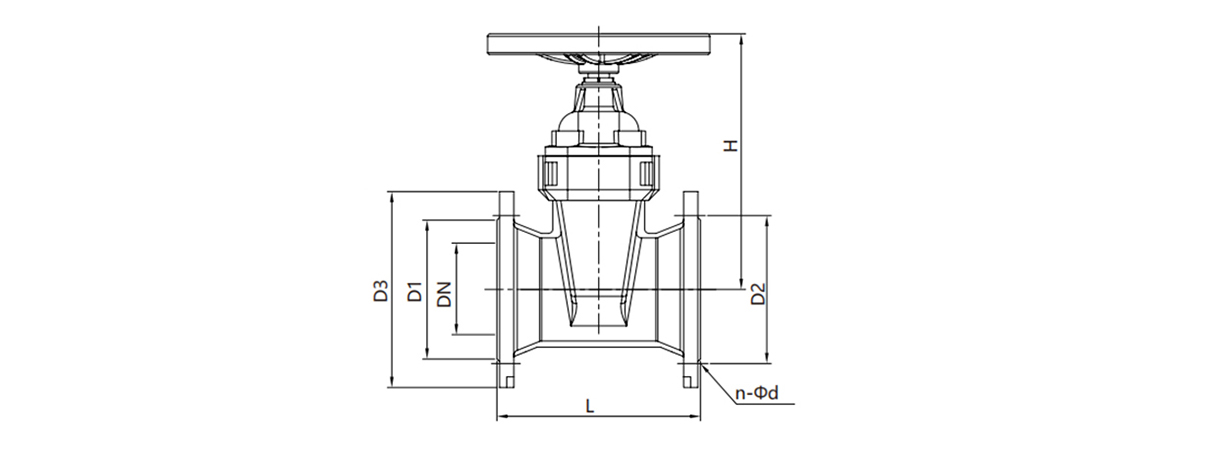

| DN | L | D | K | G | A | B | C | N-ød | H | ||||

| PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | PN10 | PN16 | ||||||

| 40 | 140 | 150 | 150 | 110 | 110 | 88 | 88 | 3 | 19 | 180 | 4-ø19 | 4-ø19 | 240 |

| 50 | 150 | 165 | 165 | 125 | 125 | 102 | 102 | 3 | 19 | 180 | 4-ø19 | 4-ø19 | 250 |

| 65 | 170 | 185 | 185 | 145 | 145 | 122 | 122 ! | 3 | 19 | 180 | 4-ø19 | 4-$19 | 280 |

| 80 | 180 | 200 | 200 | 160 | 160 | 138 | 138 | 3 | 19 | 200 | 8-ø19 | 8-ø19 | 330 |

| 100 | 190 | 220 | 220 | 180 | 180 | 158 | 158 | 3 | 19 | 200 | 8-ø19 | 8- ø19 | 361 |

| 125 | 200 | 250 | 250 | 210 | 210 | 188 | 188 | 3 | 19 | 250 | 8-ø19 | 8-ø19 | 415 |

| 150 | 210 | 285 | 285 | 240 | 240 | 212 | 212 | 3 | 19 | 250 | 8-ø23 | 8-ø23 | 460 |

| 200 | 230 | 340 | 340 | 295 | 295 | 268 | 268 | 3 | 20 | 280 | 8-ø23 | 12-ø23 | 572 |

| 250 | 250 | 395 | 405 | 355 | 355 | 320 | 320 | 3 | 22 | 320 | 12-ø23 | 12-ø28 | 658 |

| 300 | 270 | 445 | 460 | 410 | 410 | 378 | 378 | 4 | 25 | 350 | 12-ø23 | 12-ø28 | 758 |

| 350 | 290 | 505 | 520 | 470 | 470 | 438 | 438 | 4 | 27 | 450 | 16-923 | 16-ø28 | 800 |

| 400 | 310 | 565 | 580 | 515 | 525 | 490 | 490 | 4 | 28 | 550 | 16-ø27 | 16-ø31 | 900 |

| 500 | 350 | 670 | 715 | 620 | 650 | 595 | 610 | 4 | 32 | 650 | 20-ø27 | 20-ø34 | 1100 |

| 600 | 390 | 780 | 840 | 725 | 770 | 690 | 727 | 4 | 36 | 660 | 20-ø31 | 20-ø37 | 1240 |

Advantages of BS resilient seated gate valve!

-

Overall rubber coating

The overall coating of the inside and outside of the disc is used with high-quality rubber, and the domestic leading rubber vulcanization technology is

used to keep the valve that maintains accurate geometric size. More importantly, the high stickiness between rubber and disc sticks the rubber stably

together and has good elastic memory.

W -

Strong corrosion resistance

The valve body is coated with epoxy resin powder to prevent the valve from corrosion and rust, and the valve can be used for the wastewater system.

It is difficult to break, and the traditional gate valve has broken due to impact or collision with other objects. The new valve body material is ductile

iron, which significantly reduces the broken condition of this material.

E -

Non -toxic epoxy resin coating

Due to the internal and non-toxic epoxy resin coating inside the valve body, the surface of the inside and outside of the valve is completely covered

with rubber. Rust or corrosion will not occur, which ensures that the water can drink.

S -

The valve body uses precision casting

The valve body is made of precision, and the precise geometric shape makes it possible to ensure the sealing of the valve without any other

processing inside the valve.

D -

Better sealing performance

The soft sealing gate valve uses soft materials such as rubber to achieve sealing between the wedge disc and the seat. The sealing effect is

better; it can adapt to a complex environment and has higher sealing reliability and service life.

O -

Lower maintenance costs

The sealing ring of the soft sealing gate valve is made of highly elastic materials. It has a long service life and can save more maintenance

costs. At the same time, the valve body is made of ductile iron. The weight is about 20% to 30% lighter than the traditional valve. It is

easy to install and maintain and can reduce maintenance costs and time.

M -

Smaller traffic noise

The material of the soft sealing gate valve can effectively reduce the flow noise of the fluid through the valve, make it work more stable,

and be suitable for occasions with higher requirements for flow noise.

S

Project Name: Tanzania Water Project

Main Products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client Feedback:

The customer sent us the installation pictures of the WEIZIDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project Pictures:

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.