Lug type butterfly valve for high pressure

Size scope: DN40-DN 1200

Design standard: API609, ANSI16.34, JISB2064, GB T12238

Test inspection: API598

Working temperature: NBR O-70℃. EPDM o-80℃

Working pressure:PN10-16

Suitable medium: Water

Send E-mail:info@wsdvalve.com Mobile: +86-173197327665

Butterfly Valve has existed for a long time and has a wide range of applications. They first appeared in the 1930s and have been used by many industries since then. Butterfly Valves are usually made of cast iron and the name comes from the functionality of the disc.

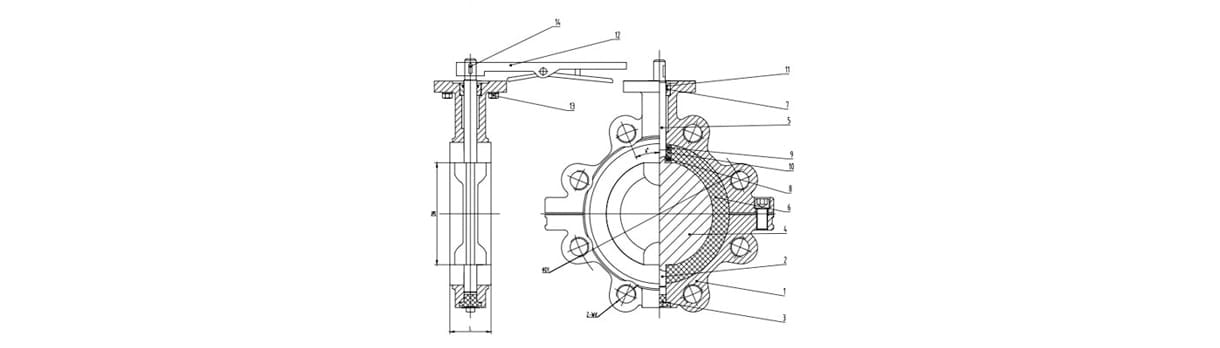

The Lugged body is compact but has a series of lugs cast into the body which are tapped with a metric thread for the fixing of a Table E flange on one side at a time. The benefit of this being the valve can be mounted at the end of a pipeline without the need for a flange on the downstream (discharge) side of the valve.

Our general purpose Cast Iron Resilient Seat Butterfly Valves are widely used thanks to their excellent performance suitable for a wide range of applications. This product is ideal for throttling or shutting off the flow of gases, liquids, semi-liquids and even solid powder.

Why choose us!

-

WEZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards

for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

W -

The product has an independent identity to ensure traceability

Each WEZIDOM product has its own unique identification number, to ensure product traceability.

E -

Provide material inspection report

All WEZIDOM products can provide the material inspection report of the main parts.

S -

One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

D -

WEZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEZIDOM has always been noticed all over the world, and trust comes from quality.

O -

WEZIDOM has a strict quality control system

WEZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

M

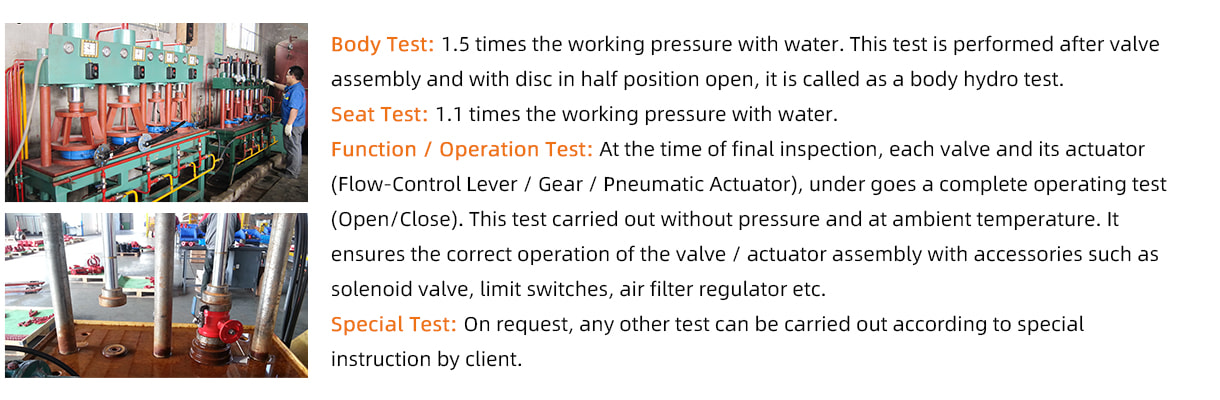

Standard Test

Factory Tour

WEZIDOM GROUP consists of 5 factories and 4 overseas branches. The five factories are mainly located in Tianjin, Hebei, Shandong, Lianyungang and Wenzhou. The four foreign branches are located in Tanzania, Zambia, Kenya and Indonesia.

| DN | A | B | C | D | ISO5211 | n-ød | K | E | D1 | N-M | ||

| PN10 | PN16 | PN10 | PN16 | |||||||||

| 50 | 161 | 80 | 42 | 52.9 | F07 | 4-09 | 90 | 70 | 125 | 125 | 4-M16 | 4-M16 |

| 65 | 175 | 89 | 44.7 | 64.5 | F07 | 4-ø9 | 90 | 70 | 145 | 145 | 4-M16 | 4-M16 |

| 80 | 181 | 95 | 45.2 | 78.8 | F07 | 4-ø9 | 90 | 70 | 160 | 160 | 8-M16 | 8-M16 |

| 100 | 200 | 114 | 52 | 104 | F07 | 4-ø9 | 90 | 70 | 180 | 180 | 8-M16 | 8-M16 |

| 125 | 213 | 127 | 55.4 | 123.3 | F07 | 4-ø9 | 90 | 70 | 210 | 210 | 8-M16 | 8-M16 |

| 150 | 226 | 139 | 55.8 | 155.1 | F07 | 4-ø9 | 90 | 70 | 240 | 240 | 8-M20 | 8-M20 |

| 200 | 260 | 175 | 60.6 | 202.5 | F10 | 4-ø12 | 125 | 102 | 295 | 295 | 8-M20 | 12-M20 |

| 250 | 292 | 203 | 65.6 | 250.5 | F10 | 4-ø12 | 125 | 102 | 355 | 355 | 12-M20 | 12-M24 |

| 300 | 337 | 242 | 76.9 | 301.6 | F10 | 4-ø12 | 125 | 102 | 410 | 410 | 12-M20 | 12-M24 |

| 350 | 368 | 267 | 76.5 | 333.3 | F10 | 4-ø12 | 125 | 102 | 470 | 470 | 16-M20 | 16-M24 |

| 400 | 400 | 309 | 86.5 | 389.6 | F14 | 4-ø18 | 197 | 140 | 525 | 525 | 16-M24 | 16-M27 |

| 450 | 422 | 328 | 102 | 440.5 | F14 | 4.ø18 | 197 | 140 | 585 | 585 | 20-M24 | 20-M27 |

| 500 | 480 | 361 | 127 | 4916 | F14 | 4-ø18 | 197 | 140 | 650 | 650 | 20-M24 | 20-M30 |

| 600 | 562 | 459 | 152 | 592.5 | F14 | 4-ø18 | 197 | 140 | 770 | 770 | 20-M27 | 20-M33 |

| 700 | 624 | 520 | 163 | 695 | F25 | 8-ø18 | 300 | 254 | 840 | 840 | 24-M27 | 24-M33 |

| 750 | 660 | 539 | 167 | 745 | F25 | 8-ø 18 | 300 | 254 | 900 | 900 | 24-M30 | 24-M33 |

| 800 | 672 | 591 | 188 | 795 | F25 | 8-ø18 | 300 | 254 | 950 | 950 | 24-M30 | 24-M36 |

| 900 | 720 | 656 | 203 | 865 | F25 | 8-ø18 | 300 | 254 | 1050 | 1050 | 28-M30 | 28-M36 |

| 1000 | 800 | 721 | 216 | 965 | F25 | 8-ø18 | 300 | 254 | 1160 | 1170 | 28-M33 | 28-M39 |

| 1200 | 941 | 864 | 276 | 1180 | F30 | 8-ø22 | 350 | 298 | 1380 | 1390 | 32-M36 | 32-M45 |

Advantages of WEZIDOM butterfly valve!

-

The thickness of valve body wall is up to standard

The valve body wall thickness meets the requirement of GB 26640, the thickness is up to the standard, and the pressure strength is guaranteed.

W -

Valve body/valve plate is made of QT450-10 material

Valve body valve plate is made of qt450-10 material with spheroidization rate above grade 3, tensile strength of 450Mpa and elongation of >10%.

E -

Good sealing and long service life of valve seat

The valve seat is made of imported rubber material, with more than 50% rubber content; Elongation at break greater than 350%, valve sealingreliable, long

life.

S -

Soft back with wide side seat

Soft backrest wide side valve seat, is advantageous to the valve installation, in the pipeline and flange boss contact surface is wide, sealing performance

is reliable. Life is longer than a hard back. And easy to remove and replace.

D -

No pin structure to avoid corrosion

Butterfly plate and valve shaft adopt through shaft without pin structure to avoid leakage caused by hole mounting pin and accelerated corrosion caused

by coating damage.

O -

Valve body is sprayed with Aksu epoxy powerd

The valve body is sprayed with world-renowned Aksu epoxy resin powder, which has stronger adhesion and better environmental tolerance after melting and curing.

M

Pakistan Sewage Treatment Plant Project

Main Products: Flanged/lug Butterfly Valves and Gate Valves

This case is an old customer from Pakistan. Because he has purchased valve products from WEZIDOM many times, he has very high trust and evaluation on WEZIDOM. He needs a lot of butterfly valves and gate valve products in the sewage treatment plant project which he is responsible for. They sent the requirements to the businessman of WEZIDOM's international trade department without hesitation. Of course, WEZIDOM still returns this old customer in Pakistan with high-quality products and preferential prices;

After that, the customer also sent us the installation pictures of the WEZIDOM product in the working condition project, and feedback that the quality is still very good, and will maintain a long-term cooperative relationship with WEZIDOM;

Project pictures:

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.