Electric three-eccentric metal hard seal butterfly valve

Size Range: DN40~DN2000

Pressure: 0.6MPa~4.0MPa

Valve design:BS 5155,EN593,API609

Face to Face:BS EN558-1,ANSIB16.10-92

Pressure test:API598,FIS2003-87,GB/T 13927-92

Send E-mail:info@wsdvalve.com Mobile: +86-173197327665

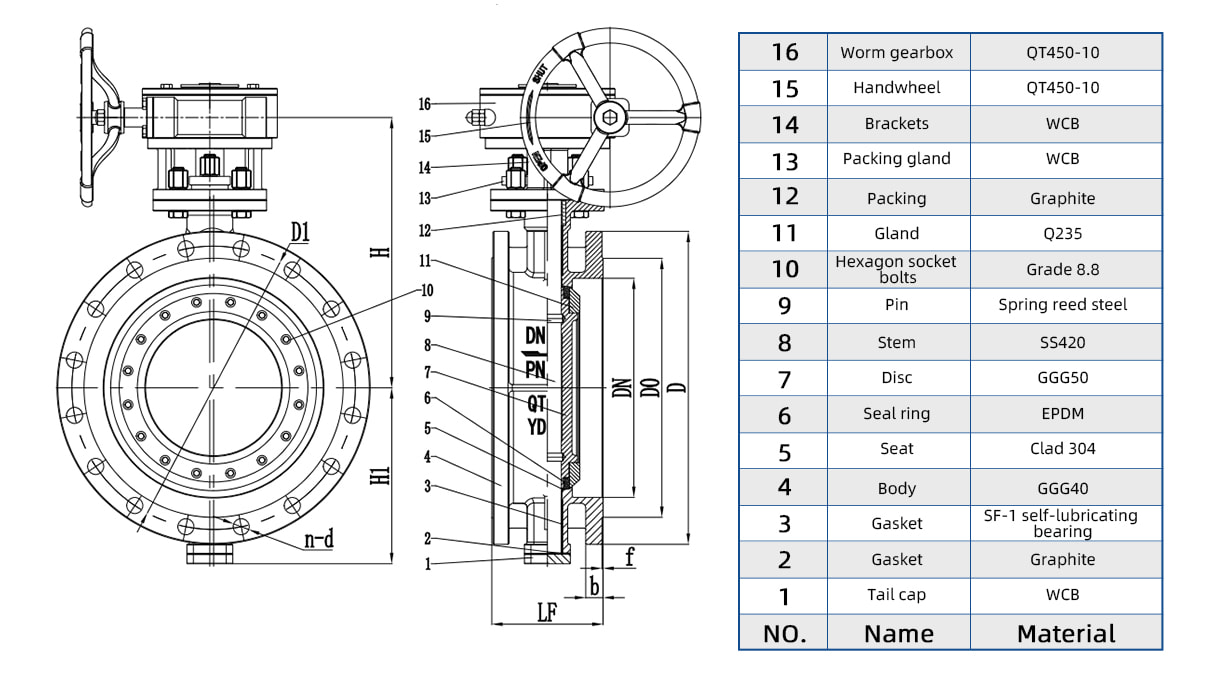

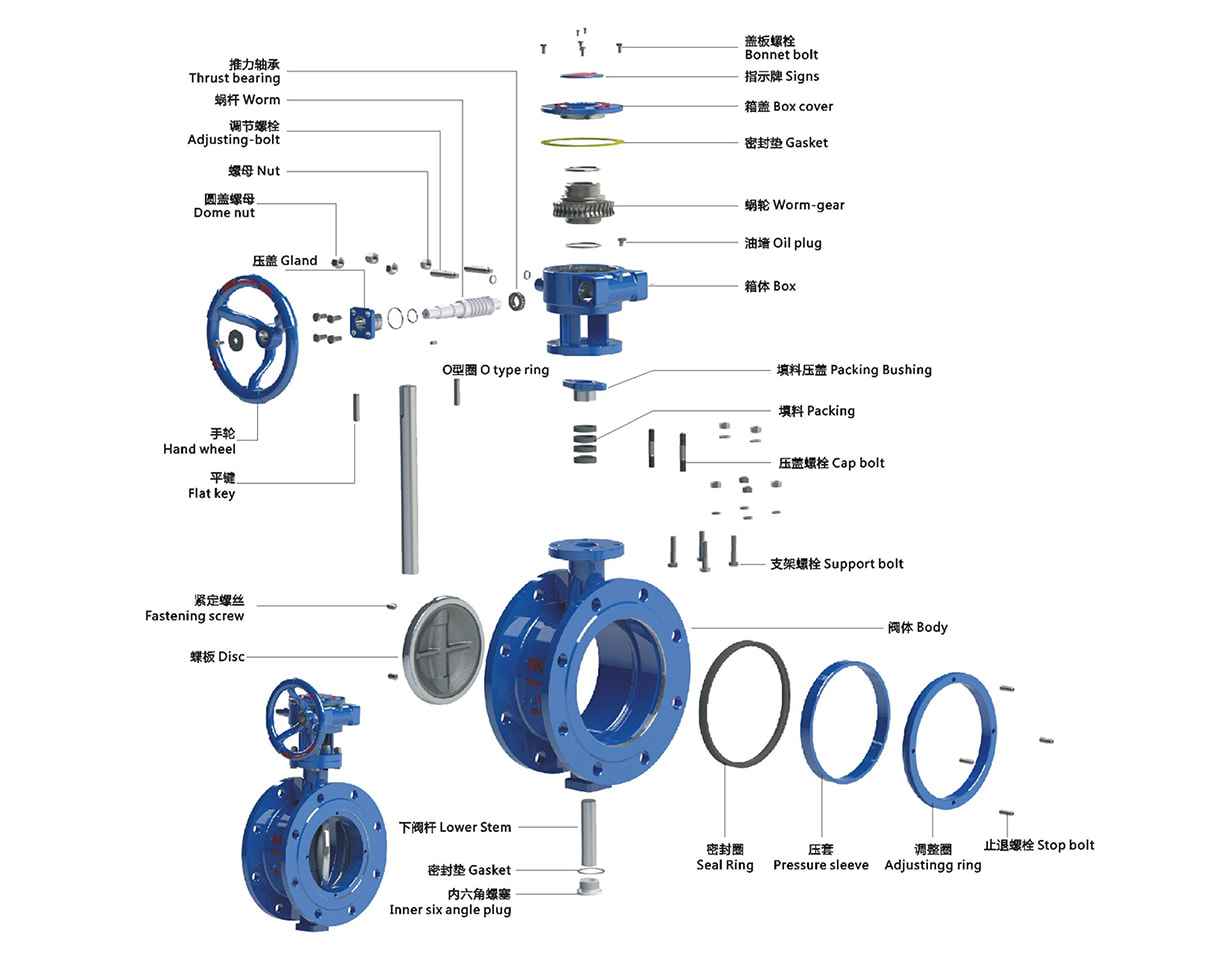

The design principle of a three-eccentric metal hard seal butterfly valve is based on the offset nature of the valve seat from the centerline of the valve shaft. The valve seat is offset in three different directions, which creates a seal that is not subject to wear and tear, even after prolonged use.

When the valve is in the closed position, the metal hard seal creates a tight seal around the valve seat, preventing fluid from passing through. When the valve is in the open position, the disc rotates around the shaft to allow fluid to pass through the valve.

The three-eccentric design of the valve also reduces the friction between the disc and the valve seat, which helps to extend the valve’s life and reduce the torque required to operate the valve. This makes the valve more efficient and easier to operate than other types of valves.

The electric actuator on the valve allows for remote operation of the valve, making it ideal for applications where manual operation of the valve is not practical or safe. The electric actuator can be programmed to open or close the valve at specific times or in response to specific conditions, providing greater control over the flow of fluids in a pipeline.

Why choose us!

-

WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards

for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

W -

The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

E -

Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

S -

One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

D -

WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

O -

WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

M

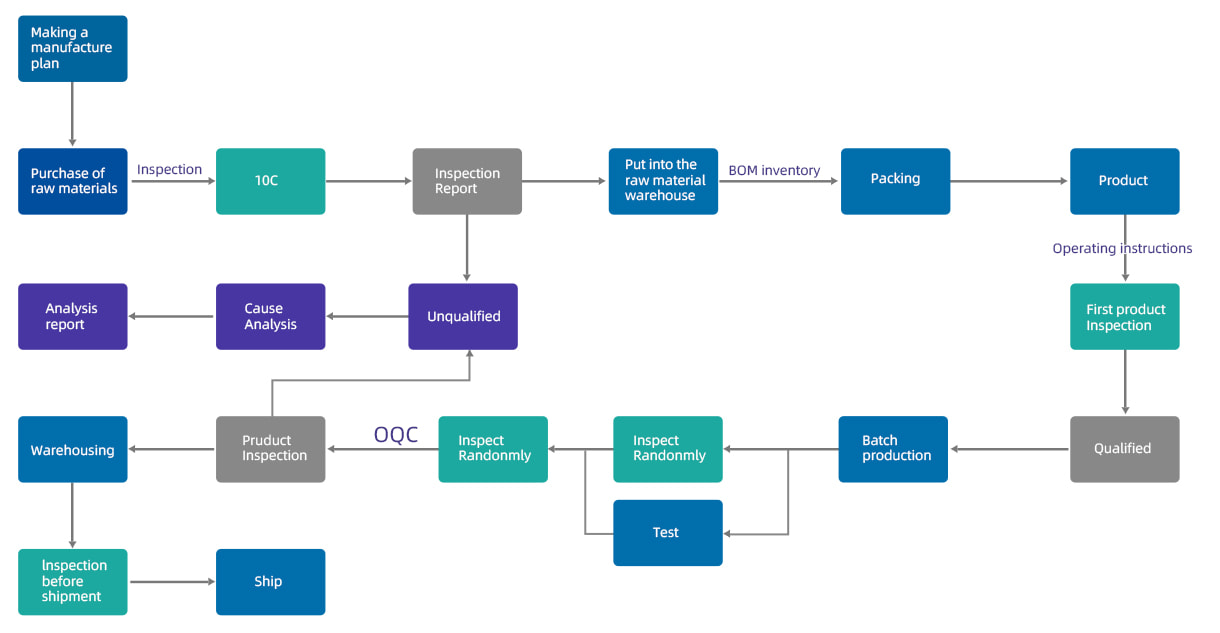

Quality Control Process

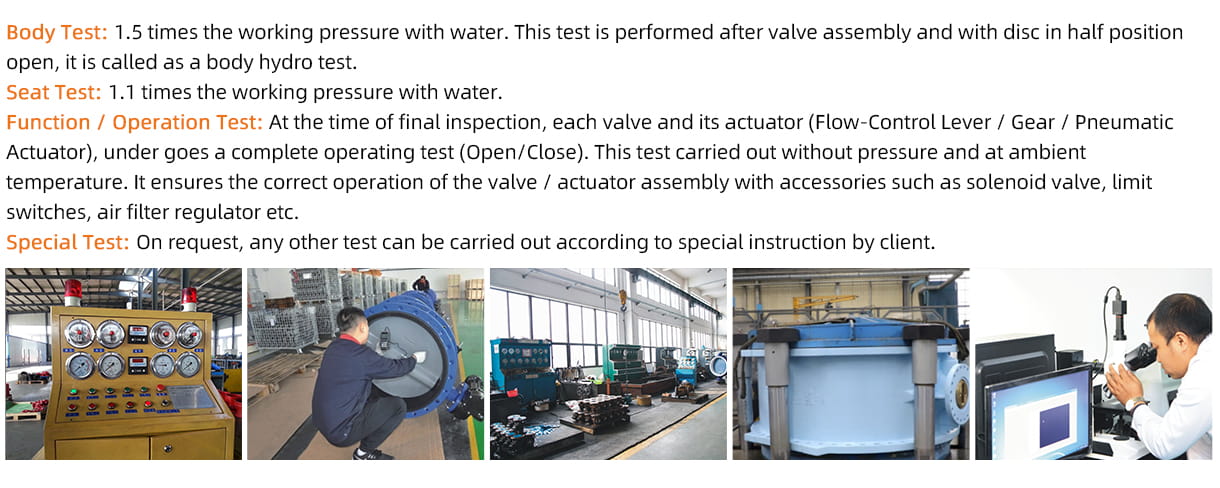

Standard Test

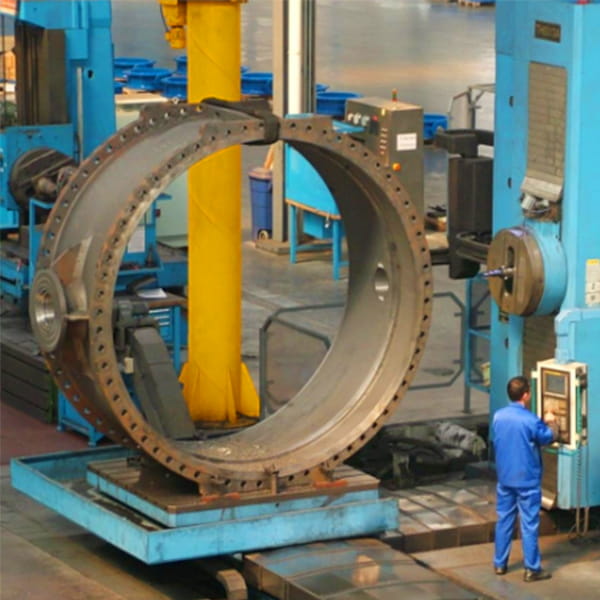

Factory Tour

WEIZIDOM GROUP consists of 5 factories and 4 overseas branches. The five factories are mainly located in Tianjin, Hebei, Shandong, Lianyungang and Wenzhou. The four foreign branches are located in Tanzania, Zambia, Kenya and Indonesia.

| DN | Main ouler size | Main connection size | |||||||||||||||

| 0.6Mpa | 1.0Mpa | 1.6Mpa | |||||||||||||||

| L | H | H1 | A | B | D | D1 | D2 | n-d | D | D1 | D2 | n-d | D | D1 | D2 | n-d | |

| 50 | 108 | 825 | 306 | 80 | 80 | 140 | 110 | 88 | 4-14 | 165 | 125 | 99 | 4-18 | 165 | 125 | 99 | 4-18 |

| 65 | 112 | 925 | 321 | 80 | 80 | 160 | 130 | 108 | 4-14 | 195 | 145 | 118 | 4-18 | 185 | 145 | 118 | 4-18 |

| 80 | 114 | 100 | 346 | 80 | 80 | 190 | 150 | 124 | 4-18 | 200 | 160 | 132 | 8-18 | 200 | 160 | 132 | 8-18 |

| 100 | 127 | 110 | 37 | 95 | 95 | 210 | 170 | 144 | 4-18 | 220 | 180 | 156 | 8-18 | 220 | 180 | 156 | 8-18 |

| 125 | 140 | 125 | 411 | 95 | 95 | 240 | 200 | 174 | 8-18 | 250 | 210 | 184 | 8-18 | 250 | 210 | 184 | 8-18 |

| 150 | 140 | 1425 | 447 | 95 | 95 | 265 | 225 | 199 | 8-18 | 285 | 240 | 211 | 8-22 | 2B5 | 240 | 211 | 8-2 |

| 200 | 152 | 170 | 607 | 190 | 300 | 320 | 280 | 254 | 8-18 | 340 | 295 | 266 | 8-22 | 340 | 296 | 266 | 12-22 |

| 260 | 165 | 1925 | 688 | 190 | 308 | 376 | 335 | 309 | 12-18 | 396 | 350 | 319 | 12-22 | 405 | 355 | 319 | 12-26 |

| 300 | 178 | 2225 | 742 | 190 | 308 | 440 | 395 | 363 | 12-22 | 445 | 400 | 370 | 12-22 | 480 | 410 | 370 | 12-26 |

| 350 | 190 | 2525 | 797 | 190 | 30B | 490 | 445 | 413 | 12-22 | 505 | 460 | 429 | 16-22 | 520 | 470 | 429 | 16-26 |

| 400 | 216 | 2825 | 930 | 270 | 486 | 540 | 495 | 463 | 16-22 | 565 | 515 | 480 | 16-26 | 580 | 525 | 480 | 16-30 |

| 450 | 222 | 3075 | 975 | 270 | 486 | 566 | 550 | 518 | 16-22 | 615 | 565 | 530 | 20-26 | 640 | 585 | 548 | 20-30 |

| 500 | 229 | 335 | 1065 | 270 | 486 | 645 | 600 | 568 | 20-22 | 670 | 620 | 6R2 | 20-26 | 715 | 650 | 609 | 20-33 |

| 600 | 267 | 390 | 1225 | 457 | 625 | 755 | 705 | 667 | 20-26 | 780 | 725 | 682 | 20-30 | 840 | 770 | 720 | 20-36 |

| 700 | 292 | 4475 | 1343 | 457 | 625 | 860 | 810 | 772 | 24-26 | 895 | 840 | 794 | 24-30 | 910 | 840 | 794 | 24-36 |

| 800 | 318 | 5075 | 1436 | 457 | 625 | 975 | 920 | 878 | 24-30 | 1015 | 950 | 901 | 24-33 | 1025 | 950 | 901 | 24-39 |

| 900 | 330 | 5575 | 1616 | 598 | 853 | 1075 | 1020 | 978 | 24-30 | 115 | 1050 | 1001 | 28-33 | 1125 | 1050 | 1001 | 28-39 |

| 1000 | 410 | 615 | 1711 | 598 | 853 | 1175 | 1120 | 1078 | 28-30 | 1230 | 1160 | 1112 | 28-36 | 1255 | 1170 | 112 | 28-42 |

| 1200 | 470 | 7275 | 1971 | 598 | 853 | 1405 | 1340 | 1295 | 32-33 | 1455 | 1380 | 1328 | 32-39 | 1485 | 1380 | 1328 | 32-48 |

| 1400 | 530 | 8375 | 2218 | 860 | 1345 | 1630 | 1560 | 1510 | 36-36 | 1675 | 1590 | 1530 | 36 -42 | 16865 | 1590 | 1530 | 36-48 |

| 1600 | 600 | 957.5 | 2578 | 880 | 1345 | 1800 | 1760 | 1710 | 40-36 | 1915 | 1820 | 1750 | 40-48 | 1990 | 1820 | 1760 | 40-56 |

| 1800 | 670 | 1067.5 | 2689 | 880 | 1345 | 2045 | 1970 | 1918 | 44-39 | 2115 | 2020 | 1950 | 4448 | 2130 | 2020 | 1960 | 44-56 |

| 2000 | 760 | 1162.5 | 3022 | 952 | 1592 | 2265 | 2180 | 2125 | 48-42 | 2325 | 2230 | 2150 | 48-48 | 2345 | 2230 | 2150 | 48-82 |

Advantages of three-eccentric metal hard seal butterfly valve!

-

Reduced friction and increased valve life

A double eccentric butterfly valve has two points of contact between the disc and the valve seat, creating a seal when the valve is closed. This design reduces the amount of torque required to operate the valve and increases the valve’s service life. However, the double eccentric design is prone to wear and tear over time, which can cause leaks and reduce the efficiency of the valve.

W -

Less prone to leakage

On the other hand, a three-eccentric metal hard seal butterfly valve has three points of contact between the disc and the valve seat, which creates a seal that is not subject to wear and tear. This design allows the valve to maintain a tight seal even after prolonged use, which reduces the risk of leaks and enhances the efficiency of the valve.

E -

Better suited to high flow, high pressure, and corrosive service conditions

Another difference between the two types of valves is in their applications. Double eccentric butterfly valves are typically used in applications where moderate to high flow rates are required, while three-eccentric metal hard seal butterfly valves are used in applications where high flow rates, high pressure, and/or abrasive or corrosive fluids are present.

S -

Corrosion-resistant

The valve is made of high-quality materials such as stainless steel or titanium, making it highly resistant to corrosion and suitable for use with corrosive fluids.

D -

Remote operation

The electric actuator on the valve allows for remote operation of the valve, making it ideal for applications where manual operation of the valve is not practical or safe.

O -

High flow capacity

The valve’s disc is designed to rotate around the shaft, allowing for high flow rates and low-pressure drops, making it ideal for applications requiring high flow capacity.

M

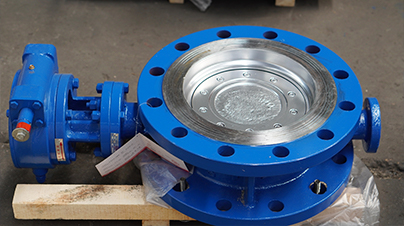

Project Name: Tanzania Water Project

Main Products: Gate Valves, Butterfly Valves, Check Valves, Pipe Fittings, etc.

Client Feedback:

The customer sent us the installation pictures of the WEIZIDOM product in the working condition project, and the feedback quality is very good, and will maintain a long-term cooperative relationship with WEIZIDOM;

Project Pictures:

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.