This series of butterfly valve is the company independent research and development of a new generation of patented products, without pin connection is through the valve rod milling flat directly connected to the butterfly plate matching, using the countersunk head bolt, assemble more convenient, more secure connection. Use three eccentric sealing structure, no mechanical wear and tear, can achieve zero leakage, have superior two-way sealing function, is used in petroleum, chemical industry, metallurgy, electric power, building materials, food, medicine, different medium such as water supply and drainage, gas transmission pipeline to adjust flow, truncation, or the best device connected to the fluid.

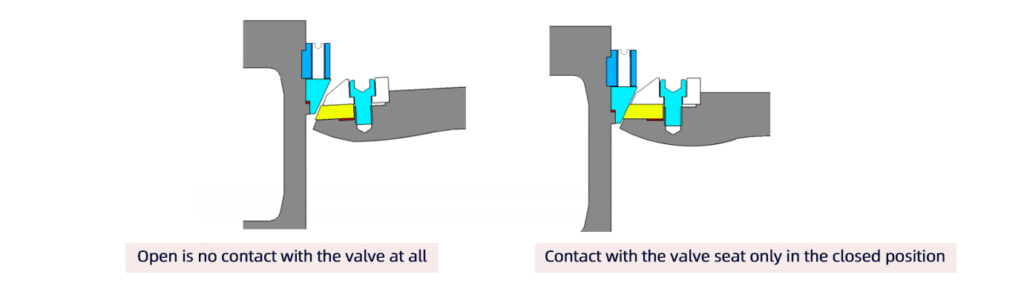

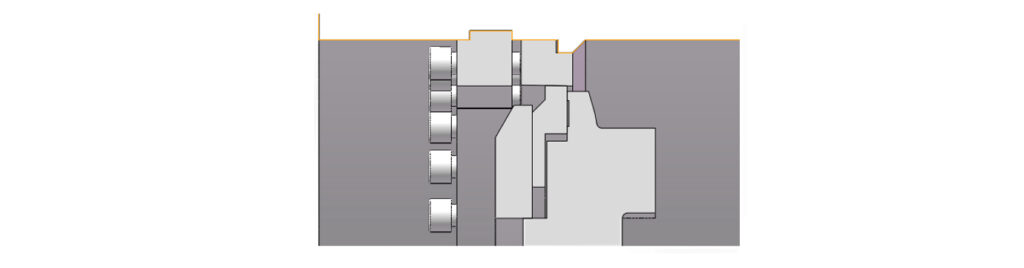

Metal sealing principle:

Open is no contact with the valve at all

Contact with the valve seat only in the closed position

Technical characteristics:

1. Dual flow direction can bear pressure and realize the installation method without flow direction restriction. Can reach the high-pressure 60OLB bidirectional pressure design requirements.

2. All-metal seal design, sealing surface using special hardening technology, to solve the high temperature, high pressure, low temperature, and other harsh conditions, the butterfly valve sealing performance of the problem.

3. Replaceable valve seat and sealing ring designed

4. Sealing parts are all metal, wear-resistant, and resistant to scouring.

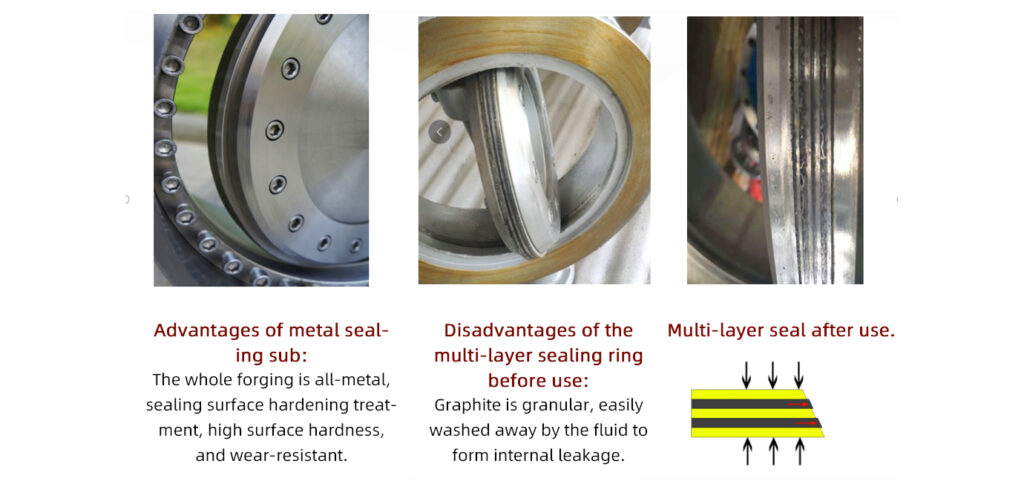

Advantages of metal sealing sub:

The whole forging is all-metal, sealing surface hardening treatment, high surface hardness, and wear-resistant.

Disadvantages of the multi-layer sealing ring before use:

Graphite is granular, easily washed away by the fluid to form internal leakage.

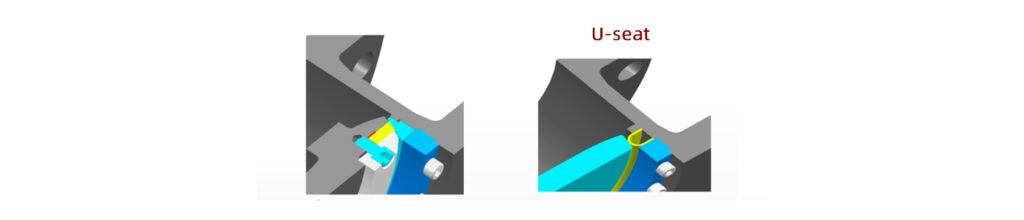

5. WESDOM all-metal sealing structure butterfly valve and U ring seal butterfly valve is the difference between the U ring seal butterfly valve is to rely on the elasticity of the sealing ring to achieve sealing, the contact surface is narrower, is a line seal, elastic failure sealing surface hardness is poor, abrasion resistance is not a high level of design defects, such cases will lead to the butterfly valve leakage, the use of short service life, to adapt to the conditions of the less problems. And wesdom’s all-metal hard seal butterfly valve completely solves such problems.

6. Wesdom’s all-metal sealed structure butterfly valve stem and actuator connection for the spline, the force is uniform without the risk of shearing the pin key, and easy to install and dismantle.

7. wesdom’s all-metal sealing structure butterfly valve valve stem and the use of upper and lower stem structure, compared with the through-axis valves can better reduce the flow resistance.

8. wesdom’s all-metal sealing structure butterfly valve with disc spring packing seal design, can automatically compensate for packing loss.

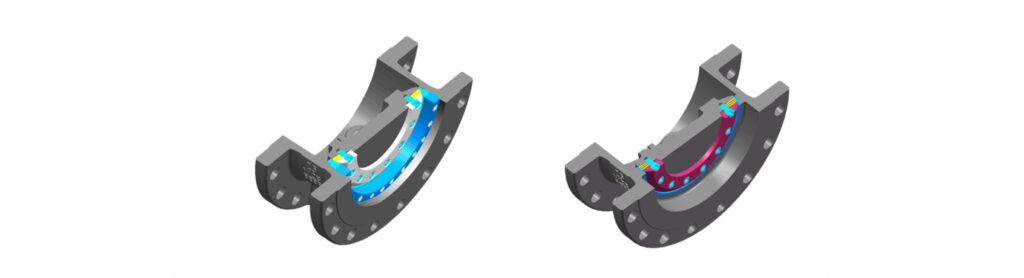

9. Z-type sealing ring valve seat design, very effectively increase the entire sealing ring in the use of the process of rigidity and strength, so that the valve in the use of the process of the structure is more solid, more stable sealing, the design is also wesdom exclusive.

Product advantages of :

Wesdom’s three eccentric butterfly valves and gate valves compared to the advantages of the list

1. The valve can be completely leakage-free, in line with API6D standard;.

2. Can achieve rapid closure, 48 “three eccentric metal-sealed butterfly valve can be shut off in 0.5 seconds.

3. Smaller opening torque, completely wear-free switching. So that the valve service life is longer, repeat the number of cut-off operations can reach 500,000 times.

4. It is not easy to be blocked.

5. It is adjustable.

6. Not easy to deform, thus reducing maintenance.

7. Not easy to deform, thereby reducing maintenance.

8. Small volume, light weight, pipeline to bear the stress of small.

Wesdom’s three eccentric butterfly valves and ball valves (soft seal) compared to the advantages of the list:

1. The valve can be completely no leakage, in line with API6D standard.

2. Intrinsically fire-resistant.

3. To achieve a frictionless rotation.

4. Smaller opening torque, completely wear-free switch. Make the valve service life longer, repeat the number of cut-off operation can reach 500,000 times.

5. Adjustable;.

6. Small volume, light weight, pipeline to bear the stress of small.

Applicable working conditions:

1. Coal chemical and chemical

2. Oil and gas

3. District heating systems

4. Water treatment and supply systems

5. Power plants

6. Desalination

7. Steel mills

8. Oil refineries