In this article, we’ll explore the 10 most common reasons why a butterfly valve fails to close completely — along with detailed solutions and preventive recommendations. Whether you’re an engineer, installer, or procurement manager, understanding these issues can help ensure long-term system performance and reduce costly downtimes.

* Fluid continues to flow even after the valve appears shut

* Visible gaps between the disc and the seat

* Actuator reaches the “closed” limit but medium still leaks

* Fluctuating pressure downstream of the valve

* Valve seems “stuck” or fails to move smoothly

In water and wastewater systems, solid particles such as sand, debris, sludge, rust, or welding residue can become trapped between the valve disc and seat. This obstruction prevents the disc from forming a tight seal.

* Disassemble the valve and remove any debris

* Install an upstream Y-strainer to block larger particles

* Clean pipeline thoroughly before valve installation

If the valve is not aligned properly during installation — especially in flanged or grooved systems — the valve body and disc may be off-center, causing uneven seating and failure to close tightly.

* Use precision tools to align the valve correctly

* Ensure flanges are parallel and not over-tightened

* Avoid pipe stress during tightening which distorts the valve body

Over time, the rubber or elastomer seat may harden, crack, or lose elasticity due to age, frequent actuation, chemical exposure, or temperature extremes. This leads to incomplete sealing.

* Replace with a new compatible seat (EPDM, NBR, PTFE, etc.)

* Choose seat material based on actual fluid and temperature range

* Follow a periodic replacement schedule for consumables

The disc (especially in metal-seated valves) may get scratched, dented, or corroded — especially in systems with abrasive or corrosive media. Even small surface damage can prevent full shutoff.

* Polish light scratches with appropriate tools

* Replace heavily damaged discs

* Select a disc material suitable for the fluid (e.g., stainless steel for corrosive media)

If a manual handle, electric actuator, or pneumatic actuator fails to reach the correct angle — due to worn gearboxes, broken linkages, or misadjusted limit switches — the valve disc may not rotate fully into the closed position.

* Recalibrate or repair the actuator

* Adjust open/close limit settings on the controller

* Check power supply and response of actuator system

A common design mistake is choosing a butterfly valve not suited for the actual pressure, temperature, or media type. For example, using a soft-seated valve in high-pressure or high-temperature systems may lead to leakage.

* Verify pressure/temperature class of the valve vs actual conditions

* Use metal-seated valves for high-temp/high-pressure flows

* Confirm compatibility with corrosive or abrasive fluids before installation

Long-term operation may wear out the stem or shaft that connects the actuator to the disc. Worn bushings or loosened stem connections result in misalignment, making it hard for the disc to close evenly.

* Inspect stem for wear or bending

* Replace bushings or stem if needed

* Lubricate the shaft periodically to reduce friction

High flow velocity, sudden closure, or improper system design can cause cavitation (formation of vapor bubbles) or water hammer, which may deform the seat or disc, causing poor closure.

* Install slow-closing actuators or anti-hammer devices

* Regulate pressure and reduce sudden valve movements

* Choose valves designed to handle high-flow or shock-prone conditions

Valves that remain in one position for months may become stuck due to corrosion, debris buildup, or seal adhesion. This can cause the valve to close incompletely or get stuck mid-travel.

* Operate valves periodically to prevent seizing

* Apply food-grade or industrial-grade lubricant to moving parts

* Plan a scheduled preventive maintenance routine

Soft-seated butterfly valves offer better sealing but are unsuitable for extreme temperatures or high mechanical stress. Metal-seated valves are more durable but provide less perfect sealing. Using the wrong type leads to leakage or closing issues.

* Analyze your system’s fluid characteristics, pressure, and temperature

* Choose soft-seated valves (EPDM/NBR) for water, non-aggressive liquids

* Use metal-seated valves (e.g., stainless steel) for steam, chemicals, or high-abrasion systems

* Visual Inspection – Look for signs of misalignment or damage

* Manual Operation Test – Confirm full travel of the disc

* Leakage Detection – Test with air or water pressure

* Disassemble & Clean – Check for internal obstructions or wear

* Consult Manufacturer – Review datasheets and installation guidelines

* Always select the right valve type for your application

* Ensure proper valve alignment during installation

* Perform regular inspections and preventive maintenance

* Avoid operating valves in extreme or unclean conditions

* Choose reliable brands that conduct 100% quality testing

WEIZIDOM is a trusted global manufacturer of industrial valves including:

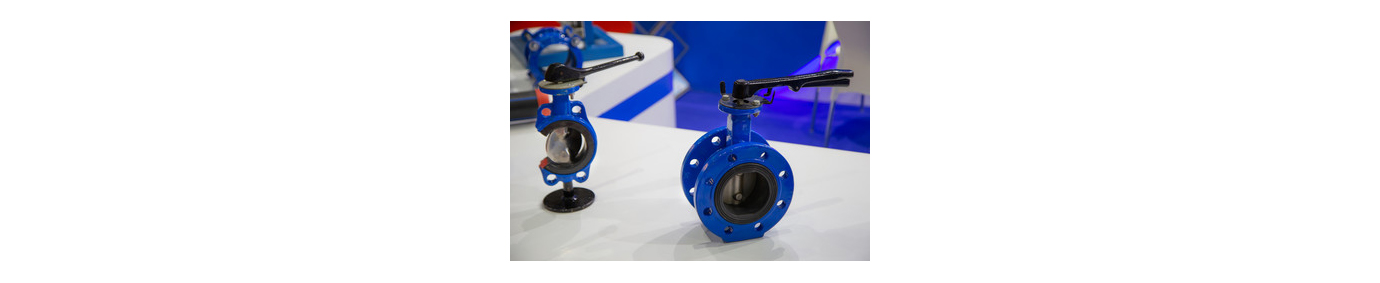

* Butterfly valves (wafer/lug/flanged)

* Foot valves, check valves, strainers

* UL/FM certified fire protection valves

* Custom OEM solutions for water, agriculture, and industrial use

✅ Durable sealing with tested quality

✅ Available in multiple sealing materials

✅ Wide range of actuators: manual, pneumatic, electric

✅ Fast delivery for global projects (Middle East, Africa, Southeast Asia)

Contact: eileen@wsdsolution.com

A butterfly valve that won’t fully close can lead to serious operational problems. But with proper installation, correct product selection, and routine maintenance, this issue can be minimized or avoided altogether. Understanding the causes outlined in this article allows engineers and technicians to troubleshoot effectively, protect system integrity, and extend valve life.

Looking for a reliable valve supplier? Consider WEIZIDOM for your next project!