❌ Failed project inspection

❌ Leakage or pressure drop

❌ Premature valve aging or failure

❌ Frequent replacements and skyrocketing maintenance costs

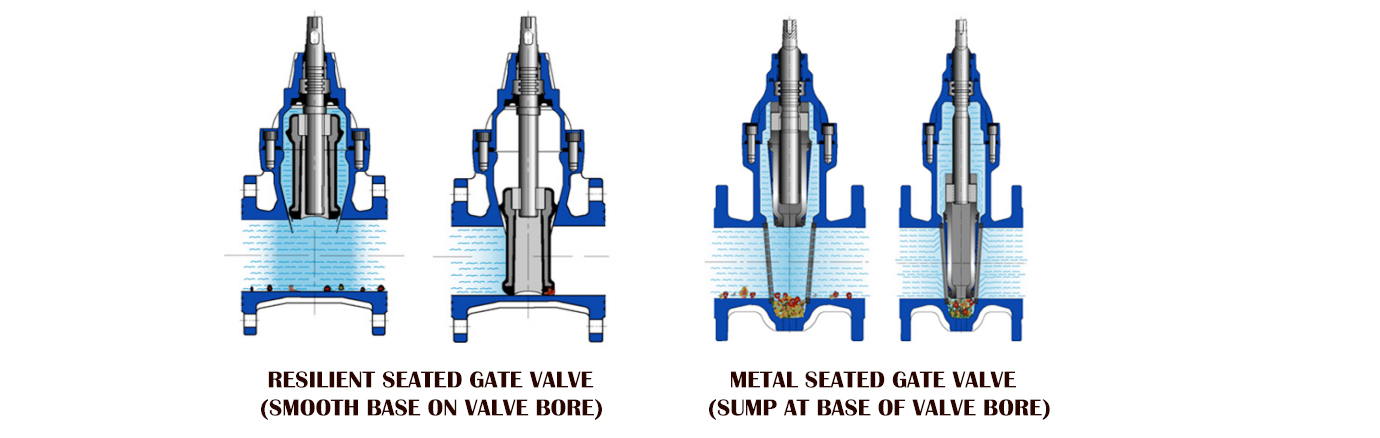

Especially when deciding between resilient seated gate valves and metal seated gate valves, a wrong choice in sealing method could lead to frequent failures, system corrosion, or even shutdowns.

But making the right decision can save costs, improve stability, and significantly extend system life.

This article will help you fully understand the structural differences, applicable conditions, pros and cons of both valve types, and guide you to choose the most suitable option for your project.

|

Comparison Item |

||

|

Sealing Material |

Rubber coated (EPDM/NBR) |

Stainless steel, alloy steel, bronze |

|

Sealing Effectiveness |

Zero leakage, ideal for clean water systems |

Acceptable micro-leakage, for industrial use |

|

Operating Temperature |

≤ 80°C (some EPDM rated up to 120°C) |

Up to 400°C or more |

|

Pressure Rating |

PN10~PN16 standard |

Up to PN25~PN40 or higher |

|

Corrosion Resistance |

Moderate, depends on rubber quality |

High, suitable for aggressive media |

|

Torque Required |

Low, easy to operate |

Higher, needs stronger actuator |

|

Wear Resistance |

Average, rubber aging risk |

High, sealing surfaces can be re-machined |

|

Cost |

Low, cost-effective |

Higher initial cost, more economical long-term |

|

Typical Applications |

Clean water, firefighting, municipal, irrigation |

High temp/pressure, corrosive or slurry fluid |

* Media: Clean, non-corrosive water

* Low-pressure systems (PN10–PN16)

* Ambient temperature ≤ 80°C

* Space limitations (lightweight design needed)

* Limited budget, looking for cost-efficiency

* Municipal water pipelines

* Fire protection systems

* Agricultural irrigation

* Residential secondary water supply

* Building piping

* Drinking water treatment

* Fluid contains particles, sand, acids, oils

* High temperature (e.g., steam) is involved

* Frequent operation requires abrasion resistance

* Rubber aging is unacceptable

* Critical systems requiring long-term reliability

* Thermal pipelines

* Boiler systems in power plants

* Chemical transport of acidic/alkaline fluids

* Petroleum refining units

* Slurry and waste treatment

* High-temp or overpressure pipelines

* Pulp and paper systems

Clean water → Resilient seated

Acid/alkaline/solid media → Metal seated

Low temp/low pressure → Resilient

High temp/high pressure → Metal

Short-term + budget constraints → Resilient

Long-term + reliability focused → Metal

With customers in 60+ countries, WEIZIDOM manufactures a full range of both resilient and metal seated gate valves tailored for various applications.

Nominal sizes: DN50~DN1200

Pressure class: PN10 / PN16 / PN25 / PN40

Body materials: Ductile iron, carbon steel, stainless steel 304/316, rubber lined

Sealing options: EPDM, NBR, stainless steel, bronze alloy

Actuators: Handwheel, electric, pneumatic, gear operated

Philippines: Resilient gate valves in water utility network — over 5 years of maintenance-free service

Bangladesh: Stainless steel metal seated valves used in acid pipelines — high stability

Nigeria: Over 100 sets of DN600 resilient gate valves used in underground trunk mains upgrade

* 100% pressure and sealing tests before shipment

* Full OEM/ODM customization (logo, color, packaging, connections)

* Engineering support: drawings, selection advice, logistics coordination

* ISO9001 certified, products compliant with EN, GB, API standards

▶ Depends on the application. Metal seated valves are better for high-temp, high-pressure, or corrosive conditions. Resilient valves are ideal for clean water systems.

▶ When installed properly with quality rubber, resilient valves can achieve near-zero leakage.

▶ If fluid contains debris or the valve operates frequently, we recommend wear-resistant designs with guide support.

▶ Metal seated valves made of stainless steel are better suited for strong acid or alkali environments.

▶ Typically 5–8 years under clean conditions and low-frequency use. Longer if well maintained.

▶ Absolutely! Our engineers offer free technical consultation and selection support via WhatsApp or email.

Different sealing structures = different durability, maintenance frequency, and system safety.

Whether you’re an EPC contractor, project purchaser, or end user — choosing the right gate valve is critical to your system’s efficiency, longevity, and cost control.

Let WEIZIDOM help you make the right choice, with confidence and professionalism.

Website: www.wsdsolution.com