Stainless steel wafer butterfly valve

Size:2”~40”

Pressure Rating:PN10, PN16, CL150, JIS 5K/10K

Material: SS304, SS316

Design Standard:EN 593, MSS SP67, API 609, BS5155

Inspection Standard:API 598, ISO 5208, EN 12266

Application medium:water, oil and gas

Send E-mail:info@wsdvalve.com Mobile: +86-173197327665

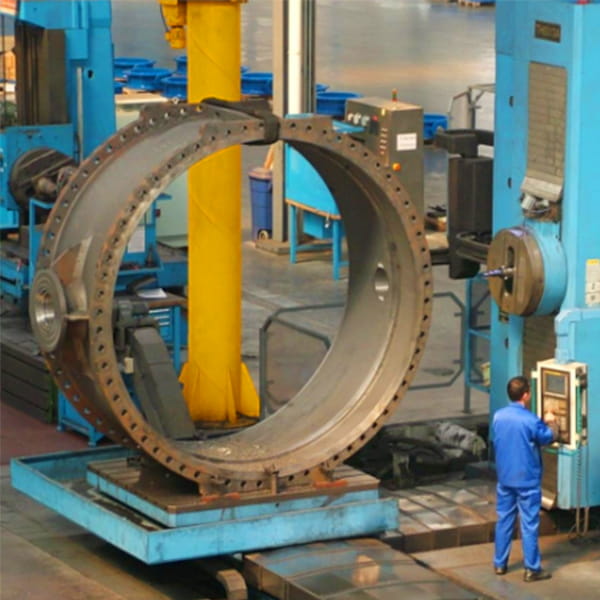

A stainless steel butterfly valve is a type of valve that is made of stainless steel and consists of a circular disc or vane that is mounted on a shaft. The disc can be rotated to control the flow of fluid or gas through the valve. The valve is called a butterfly valve because the shape of the disc resembles the wings of a butterfly.

Stainless steel butterfly valves are commonly used in industries such as food and beverage, pharmaceutical, and chemical processing, where high levels of hygiene and corrosion resistance are required. Stainless steel is an ideal material for these applications because it is resistant to corrosion and can withstand high temperatures and pressures.

Stainless steel butterfly valves can be operated manually, electrically, or pneumatically, depending on the application. They are known for their quick response times, low pressure drop, and ease of installation and maintenance, which makes them a popular choice for many industries.

Why choose us!

-

WEIZIDOM patent products, patent certification

The product side flanges comply with national, German, Russian, American, British and Japanese standards and other domestic and international standards

for multiple pressures, easy connection and wide adaptability, which can reduce the type of purchase and stock.

W -

The product has an independent identity to ensure traceability

Each WEIZIDOM product has its own unique identification number, to ensure product traceability.

E -

Provide material inspection report

All WEIZIDOM products can provide the material inspection report of the main parts.

S -

One-stop service

One-stop service, we not only supply high quality products, also supply solutions and after-sales service.

D -

WEIZIDOM has a lot of project experience

We have a lot of project experience in countries such as Pakistan and the Philippines, WEIZIDOM has always been noticed all over the world, and trust comes from quality.

O -

WEIZIDOM has a strict quality control system

WEIZIDOM has a strict quality control system and before delivery, we test 100% of each product to ensure its quality, promising you a high quality product.

M

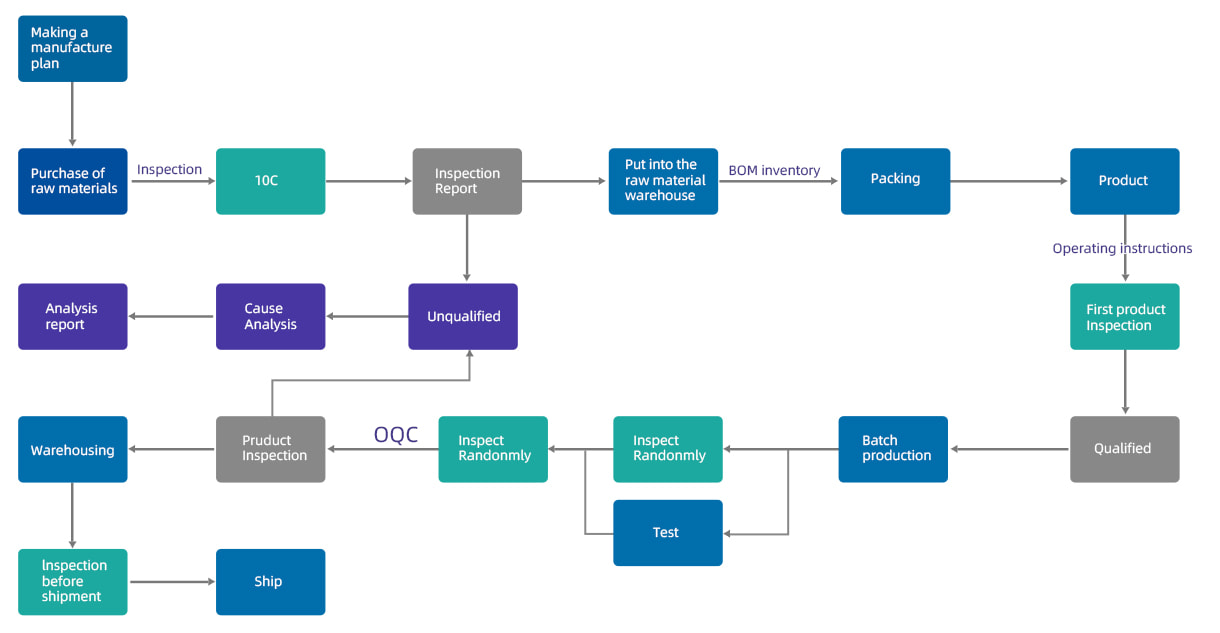

Quality Control Process

Standard Test

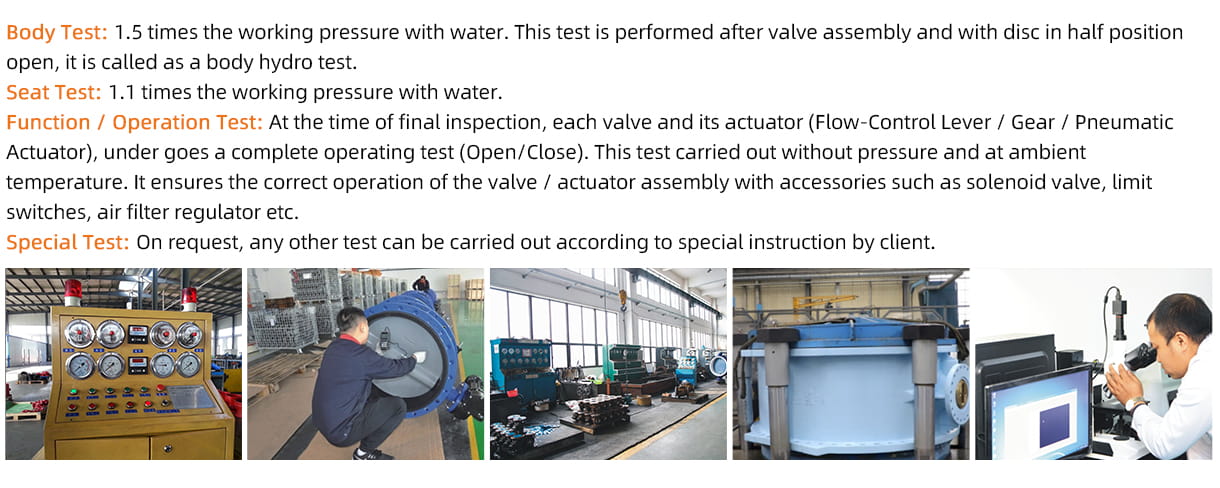

Factory Tour

WEIZIDOM GROUP consists of 5 factories and 4 overseas branches. The five factories are mainly located in Tianjin, Hebei, Shandong, Lianyungang and Wenzhou. The four foreign branches are located in Tanzania, Zambia, Kenya and Indonesia.

|

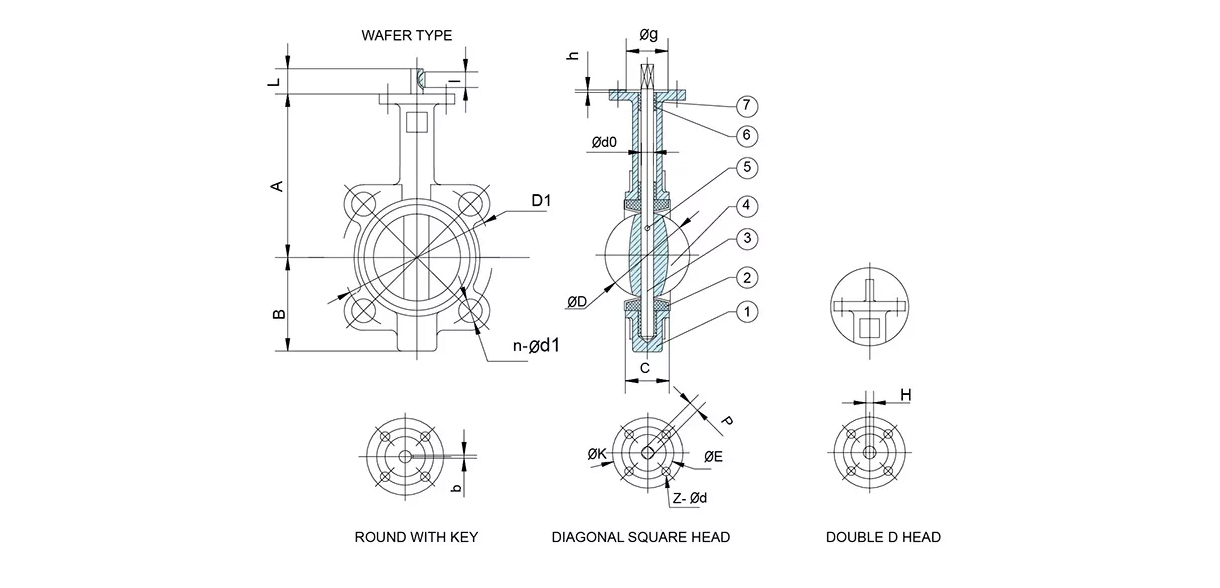

SIZE |

A |

B |

C |

L |

ANSI 150B |

DIN PN 10 |

DIN PN 16 |

JIS 10K |

ISO 5211 |

Top Flange |

|||||||

|

mm |

in |

øK |

N-ød |

øK |

N-ød |

øK |

N-ød |

øK |

N-ød |

øD |

øD1 |

N-øG |

|||||

|

40 |

1.5″ |

67 |

141 |

32 |

33 |

98.5 |

4-ø16 |

110 |

4-ø18 |

110 |

4-ø18 |

105 |

4-ø19 |

65 |

50 |

4-ø8 |

F05 |

|

50 |

2″ |

67 |

141 |

32 |

43 |

120.6 |

4-ø19 |

125 |

4-ø18 |

125 |

4-ø18 |

120 |

4-ø19 |

65 |

50 |

4-ø8 |

F05 |

|

65 |

2½” |

75 |

151 |

32 |

46 |

139.7 |

4-ø19 |

145 |

4-ø18 |

145 |

4-ø18 |

140 |

4-ø19 |

65 |

50 |

4-ø8 |

F05 |

|

80 |

3″ |

95 |

160 |

32 |

46 |

152.4 |

4-ø19 |

160 |

8-ø18 |

160 |

8-ø18 |

150 |

8-ø19 |

65 |

50 |

4-ø8 |

F05 |

|

100 |

4″ |

111 |

180 |

32 |

52 |

190.5 |

8-ø19 |

180 |

8-ø18 |

180 |

8-ø18 |

175 |

8-ø19 |

90 |

70 |

4-ø10 |

F07 |

|

125 |

5″ |

129 |

193 |

32 |

56 |

215.9 |

8-ø22.4 |

210 |

8-ø18 |

210 |

8-ø18 |

210 |

8-ø23 |

90 |

70 |

4-ø10 |

F07 |

|

150 |

6″ |

142 |

207 |

32 |

56 |

241.3 |

8-ø22.4 |

240 |

8-ø22 |

240 |

8-ø22 |

240 |

8-ø23 |

90 |

70 |

4-ø10 |

F07 |

|

200 |

8″ |

170 |

240 |

45 |

60 |

298.4 |

8-ø22.4 |

295 |

8-ø22 |

295 |

12-ø22 |

290 |

12-ø23 |

125 |

102 |

4-ø12 |

F10 |

|

250 |

10″ |

206 |

270 |

45 |

68 |

361.9 |

12-ø25.4 |

350 |

12-ø22 |

355 |

12-ø26 |

355 |

12-ø25 |

125 |

102 |

4-ø12 |

F10 |

|

300 |

12″ |

238 |

316 |

45 |

78 |

431.8 |

12-ø25.4 |

400 |

12-ø22 |

410 |

12-ø26 |

400 |

16-ø25 |

125 |

102 |

4-ø12 |

F10 |

|

350 |

14″ |

267 |

368 |

45 |

78 |

476.2 |

12-ø28.4 |

460 |

16-ø22 |

470 |

16-ø26 |

445 |

16-ø25 |

125 |

102 |

4-ø12 |

F10 |

|

400 |

16″ |

298 |

400 |

51 |

86 |

539.7 |

16-ø28.4 |

515 |

12-ø26 |

525 |

16-ø30 |

510 |

16-ø27 |

175 |

140 |

4-ø18 |

F14 |

|

450 |

18″ |

318 |

422 |

51 |

105 |

577.8 |

16-ø31.8 |

565 |

20-ø26 |

585 |

20-ø30 |

565 |

20-ø27 |

175 |

140 |

4-ø18 |

F14 |

|

500 |

20″ |

349 |

479 |

57 |

130 |

635 |

20-ø31.8 |

620 |

20-ø26 |

650 |

20-ø33 |

620 |

20-ø27 |

175 |

140 |

4-ø18 |

F14 |

|

600 |

24″ |

410 |

562 |

70 |

152 |

749.3 |

20-ø35.1 |

725 |

20-ø30 |

770 |

20-ø36 |

730 |

24-ø33 |

210 |

165 |

4-ø22 |

F16 |

Advantages of stainless steel butterfly valve!

-

Corrosion resistance

Stainless steel is highly resistant to corrosion, making it ideal for use in harsh environments where other materials may corrode or degrade.

W -

Hygiene

Stainless steel is easy to clean and sanitize, making it suitable for applications in the food and beverage, pharmaceutical, and other industries where

hygiene is critical.

E -

Durability

Stainless steel is a strong and durable material that can withstand high temperatures and pressures, making it suitable for use in a wide range of

applications.

S -

Quick response time

Butterfly valves can be operated very quickly, which makes them suitable for applications where rapid response is required.

D -

Easy to install and maintain

Butterfly valves are relatively easy to install and maintain, which can help to reduce downtime and maintenance costs.

O -

Versatility

Stainless steel butterfly valves are available in a range of sizes and can be used for a variety of applications, from small-scale residential plumbing to

large-scale industrial processes.

M

Project Name: Famous Textile Factory Project in Pakistan

Main products: flow meters and SS valves

Project Description:

This is a relatively special case. Because the customer know less about valves, but the demand is very large. So WEIZIDOM assigns a professional team (salesmen and engineers from the International Trade Department) to conduct on-site inspections and give customer some Pertinent suggestions, and this customer are very shocked and moved by our service, and have established a long-term cooperative relationship with us without hesitation;

Project Pictures:

If you have any questions, feedback or comments, please fill out the form below and we will reply you back as soon as possible.