In the oil, gas, refining, and high-pressure chemical industries, valves are not only control components of pipeline systems but also crucial guarantees of safety and compliance. Compared to ordinary industrial valves, API valves are widely used in high-risk oil and gas operations due to their higher design standards, stricter testing requirements, and more reliable performance.

However, not all valves labeled “API” are truly suitable for project use. For procurement personnel and engineering technicians, correctly selecting valves, avoiding pitfalls, and ultimately purchasing valves that truly meet API standards is a critical issue.

API valves are not necessarily better the more advanced they are; rather, it’s about whether they match the operational requirements.

API valves should be prioritized for projects falling into the following categories:

1. Oil and gas extraction and gathering systems

2. Long-distance pipelines, stations, distribution and metering systems

3. Oil refining, petrochemical, and high-pressure chemical plants

4. High-temperature, high-pressure, flammable, explosive, and toxic media conditions

5. Systems with high requirements for fire prevention, leak prevention, and long-term continuous operation

6. When your project falls into these categories, ordinary industrial valves are sufficient:

7. Municipal water supply and drainage systems

8. HVAC systems

9. Low-pressure, non-hazardous media conditions

Therefore, the choice of API valves should be determined by the risk level of the operating condition, not simply by price or “configuration upgrades.”

Different API standards correspond to different valve types and application scenarios; choosing the wrong standard is riskier than choosing the wrong brand.

Common API Valves and Their Applications

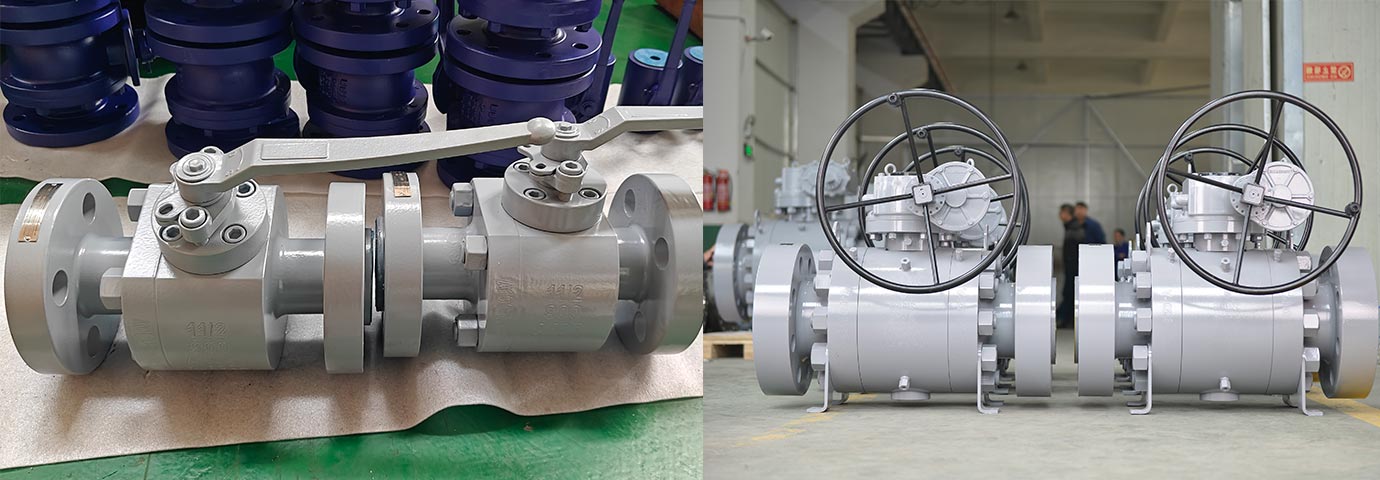

✅ API 6D Pipeline Valves

Applications: Long-distance oil and gas pipelines, stations

Types: Gate valves, ball valves, plug valves

Features: Full-bore, low leakage, high reliability

✅ API 600 / API 602 Gate Valves

Applications: Refining and chemical plants, high-pressure process pipelines

Features: Thick-walled design, strong pressure resistance

✅ API 6FA / API 607 Fireproof Valves

Applications: Flammable and explosive media systems

Features: Maintains a tight seal even under fire conditions

WEIZIDOM API valve products cover API 6D ball valves, gate valves, and fireproof valves, widely used in oil and gas transportation and energy projects.

Before requesting a quote or placing an order, it is recommended to clarify at least the following core technical conditions:

Media Type: Crude oil, natural gas, sulfur-containing media, acidic gases (Is NACE MR0175 required?)

Pressure Rating and Temperature Range: Class 150–2500? Are there high temperatures or pressure fluctuations?

Valve Structure: Full bore/reduced bore? Fixed ball/floating ball? Rising stem/non-rising stem?

Sealing Structure: Metal seal, soft seal, or composite seal? Is a double seal (DBB/DIB) required?

Fire Protection and Leakage Prevention Requirements: Is API 6FA/API 607 fire protection certification required?

Actuator: Manual, electric, pneumatic? Does it connect to a DCS or ESD system?

Experience-Based Advice: API valve selection should be driven by technical parameters, not just by model number or price.

In API valve procurement, supplier selection is often more important than product model.

A reliable API valve manufacturer should possess:

1. Authentic and valid API certifications: API 6D, API 600, and other certificates can be verified on the API website.

2. Comprehensive testing and inspection capabilities: API 598 pressure testing, fire resistance testing, and third-party witness reports.

3. Engineering project experience: Actual application cases in oil and gas, energy, and pipeline projects.

4. Material and process traceability: Clear Material Testing Center (MTC) reports and manufacturing process records.

5. Stable delivery and technical support capabilities: Ability to support project timelines, technical clarifications, and after-sales service.

WEIZIDOM, as a professional industrial valve manufacturer, has long focused on the design and manufacture of API valves, possessing a mature production system, strict quality control, and extensive experience in delivering numerous international projects.

In API valve procurement, simply pursuing the lowest price often leads to higher hidden costs:

👉 Increased leakage risk

👉 Insufficient fire resistance

👉 Shortened service life

👉 Frequent downtime and replacement

The truly rational procurement logic is: while meeting API standards and operating condition requirements, choose valve solutions with stable quality and lower total life-cycle costs.

API valves are not simply “upgraded versions” of ordinary industrial valves; they are specialized equipment designed for high-risk, high-requirement operating conditions.

Only by clearly defining the operating conditions → correctly selecting the type → choosing a reliable manufacturer can the true value of API valves be realized. WEIZIDOM is committed to providing oil and gas and energy projects with API-compliant, reliable, and consistently delivered valve solutions, helping customers achieve the best balance between safety, compliance, and cost.

Q1: What is the difference between API valves and ordinary industrial valves?

A: API valves have more stringent designs, higher pressure resistance, and superior sealing and fire resistance performance, making them suitable for oil and gas and high-pressure, high-temperature operating conditions.

Q2: What key points should be considered when purchasing API valves?

A: Choose products that meet API standards, match the operating pressure and temperature, and verify the supplier’s qualifications and engineering experience.

Q3: How to reduce the risks of valve maintenance later?

A: When selecting valves, ensure that the material matches the medium, the sealing performance is reliable, and choose experienced manufacturers such as WEIZIDOM.

Q4: Do gate valves that leak or are difficult to operate need to be replaced?

A: Yes, if the seal fails or opening and closing is abnormally frequent, replacement should be the first priority.