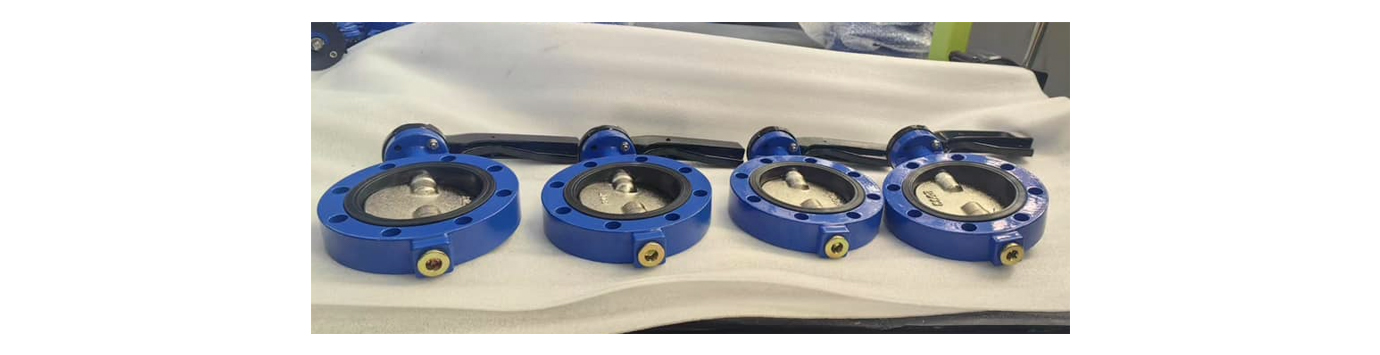

Among the various connection types, Double Flange Butterfly Valves and Single Flange Butterfly Valves are two common structural designs.

What’s the real difference between them?

Which one is better for my project?

What are their pros and cons?

This article gives you a comprehensive comparison of the two, helping you make a scientific choice and avoid engineering risks.

* Flanges on both sides of the valve body

* Disc rotates at the center to open/close the flow

* Ideal for large-diameter, high-pressure, or high-vibration systems

Single flange butterfly valves have only one flanged end, with the other end in wafer (lug) type design. They rely on bolts to clamp between the flanges of the pipeline. They are more compact and lighter, suitable for space-restricted or cost-sensitive installations.

* One flange, one wafer/lug-type end

* Suitable for small to medium diameter systems

* Often used in low-pressure or non-critical systems

|

Comparison Item |

||

|

Connection Method |

Both ends have standard flanges |

One end flange, one end clamped |

|

Installation Strength |

High, strong anti-vibration |

Weaker, relies on clamping force |

|

Maintenance |

Easy to disassemble/replace |

More complex, depends on pipe loosening |

|

Sealing Performance |

Excellent, larger sealing surface |

Moderate, smaller sealing area |

|

Applicable Size |

Medium to large (DN200 and above) |

Small to medium (DN50–DN300) |

|

Weight & Cost |

Heavier, slightly higher cost |

Lighter, more cost-effective |

|

Pressure Level |

Suitable for PN10–PN40 |

Suitable for PN6–PN16 |

High Structural Stability: Ideal for pump outlets or main pipelines exposed to vibration

Superior Sealing: Suited for systems requiring high sealing integrity such as fire pipelines and industrial water supply

Easy Maintenance: Flanged connections make replacement and maintenance convenient

Resistant to Harsh Conditions: Performs well in abrasive, high-temp, or corrosive media

* Municipal water supply systems

* Large-scale industrial cooling

* Main fire protection lines

* Chemical pipeline systems

* High-frequency operation systems

Lightweight & Compact: Great for limited space installations

Lower Installation Cost: Simple design reduces labor cost

Lower Shipping Cost: Lightweight for bulk long-distance delivery

Fits Lightweight Piping: Like PVC or PE piping

* Industrial water treatment systems

* HVAC networks

* Underground or confined spaces

* Agricultural irrigation

* OEM equipment assemblies

Pipeline pressure & flow rate: Choose double flange for higher pressure

Frequency of maintenance: Double flange is easier to remove and service

Space constraints: Single flange suits narrow spaces

Budget and lead time: Single flange is quicker and cheaper

Vibration or pressure conditions: Use double flange under such conditions

Choosing the right type of butterfly valve is crucial for system performance and safety.

Misselection may lead to sealing failures or operational hazards. The core difference lies in their structural robustness and suitable applications. Make informed decisions based on pressure, installation space, maintenance needs, and system stability.

Still unsure? Our WEIZIDOM engineering team is here to help with professional selection support and customized product services.

They differ in connection design, installation strength, sealing ability, and application range. Double flange is more robust, single flange is lighter.

Double flange butterfly valve is recommended due to stronger structure.

Best for low-pressure, lightweight, or limited-space systems like HVAC and water treatment.

Double flange valves generally offer better sealing due to larger and more stable contact surfaces.

Yes. Its lighter body and simple structure make it quicker and easier to install.

Absolutely. We support customization by material, size, drive type, and provide full project selection services.