In this in-depth guide, we will compare butterfly valves and ball valves in terms of working principles, materials, pressure ratings, sealing, and application environments—so you can confidently choose the right valve for your system.

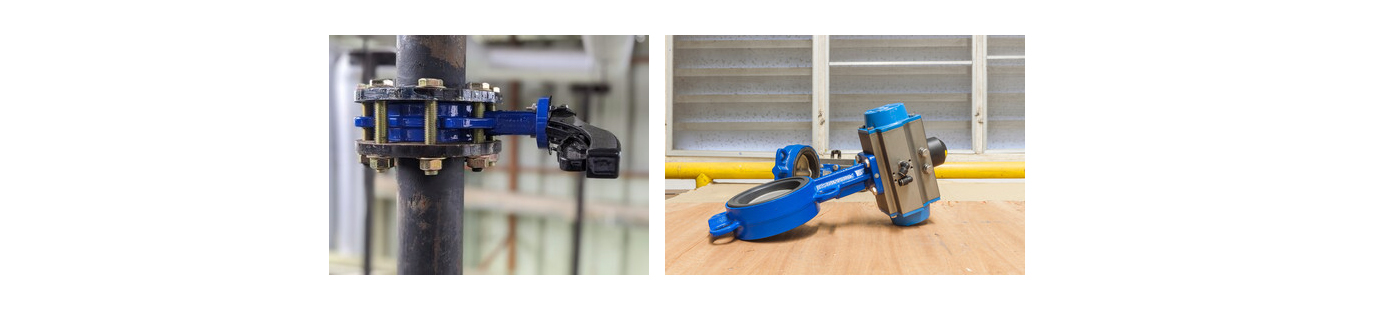

A butterfly valve is a quarter-turn valve that uses a rotating disc to regulate fluid flow.

* Water treatment plants

* HVAC systems

* Industrial ventilation

* Fire protection systems

* Compact design

* Lightweight

* Cost-effective

* Easy installation

* Suitable for non-critical sealing applications

A ball valve uses a hollow, perforated ball to start or stop fluid flow.

* Oil & gas pipelines

* Chemical processing plants

* Power stations

* High-pressure water and steam systems

* Strong pressure and temperature resistance

* Quick 90° operation

* Leak-proof sealing

* Suitable for aggressive or hazardous fluids

|

Feature |

||

|

Flow Control |

Best for large volume, low-pressure systems |

Best for full shutoff or full-on applications |

|

Sealing Performance |

Moderate sealing, may leak under high pressure |

Excellent sealing, suitable for high demands |

|

Installation Space |

Compact, great for tight spaces |

Larger, requires more space |

|

Operation |

Quarter-turn, lightweight disc |

Quarter-turn, heavier ball |

|

Cost |

Lower manufacturing and installation cost |

More expensive due to precise machining |

|

Durability |

Long service life in low-pressure settings |

High durability even with frequent use |

|

Automation Options |

Manual, electric, pneumatic, or hydraulic |

Manual, electric, pneumatic, or hydraulic |

|

Applications |

HVAC, water, fire protection, ventilation |

Oil & gas, chemicals, power, industrial fluids |

✅ Your system involves large volume flow under low pressure

✅ You have space constraints or require lightweight components

✅ You need cost-effective options for general flow control

✅ Moderate sealing is acceptable

✅ You require tight shut-off and zero leakage

✅ Your application involves high pressure or temperature

✅ Your system needs frequent opening/closing

✅ You work with chemical, corrosive, or hazardous fluids

|

Valve Type |

Common Materials |

|

Cast iron, ductile iron, stainless steel, PTFE-lined |

|

|

Stainless steel, carbon steel, brass, PTFE seats |

Material selection should be based on the fluid type, operating pressure, temperature, and corrosiveness of the environment.

At WEIZIDOM, we manufacture a complete range of butterfly valves and ball valves with international certifications and project references across 60+ countries.

✔ Water treatment

✔ Oil & gas

✔ Power generation

✔ Chemical processing

✔ Mining & metallurgy

* Factory-direct pricing

* Customization available (size, material, drive options)

* Short lead times

* Project-based engineering support

Get in touch today to receive your personalized quote or technical catalog!

Email: eileen@wsdsolution.com | WhatsApp: +86-13849184495

A: Butterfly valves are cost-effective and compact, while ball valves offer superior sealing and pressure resistance.

A: Not recommended. Use ball valves for high-pressure or high-temperature systems.

A: Ball valves are ideal for quick, full shut-off; butterfly valves are better for throttling large volumes.

A: Yes, generally butterfly valves are less expensive and easier to install.

A: Ball valves generally have longer service life in high-demand systems; butterfly valves last long under moderate use.

A: Yes, both can be automated using pneumatic, electric, or hydraulic actuators.