In the industrial fluid control field, gate valves are extremely common shutoff valves whose primary function is to connect or shut off media in a pipeline. However, within the gate valve family, knife gate valves, as a special type, differ significantly from what are commonly referred to as ordinary gate valves (or “slab gate valves”). Although both contain the word “gate valve,” their design concepts, applicable operating conditions, and performance characteristics differ significantly. A correct understanding of these differences is crucial for valve selection and ensuring safe and stable system operation.

This is the core difference between the two valves, directly determining their different application areas.

General Purpose Gate Valve

Gate Structure: The gate is typically a solid wedge-shaped or parallel double-disc design. Wedge-shaped gates achieve a seal by wedging into the valve seat when closed; parallel gates achieve a seal by using medium pressure or spring action to press the gate against the valve seat. Valve Cavity Design: The valve body’s inner cavity typically features a clear guide track to ensure smooth gate movement. The flow path is typically full-bore or reduced-bore, providing minimal resistance to media flow.

Sealing Method: This method prioritizes bidirectional sealing, meaning that when the valve is closed, it simultaneously blocks media pressure from both ends of the pipeline. The sealing element (gate and seat) requires extremely high machining precision and surface finish.

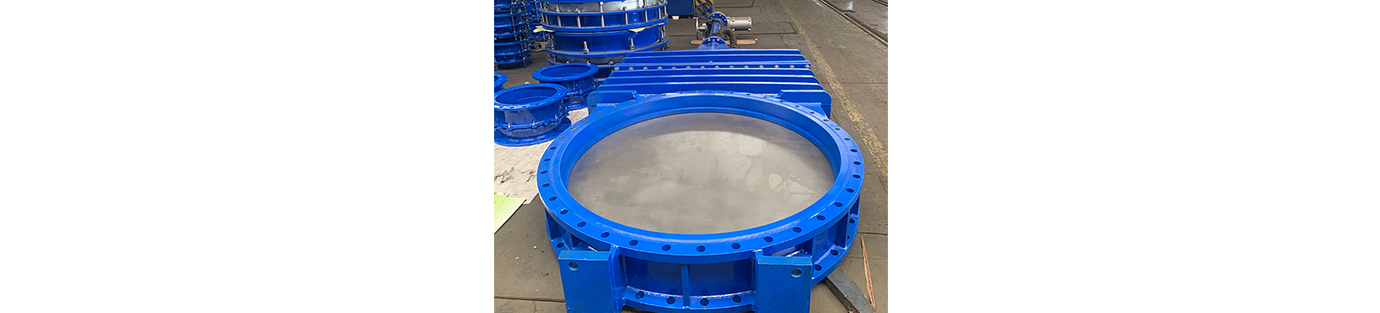

Knife Gate Valve

Gate Structure: The gate is very thin, like a sharp blade, easily cutting through and severing viscous media containing solid particles or fibers, preventing the valve from becoming stuck.

Valve Cavity Design: This design offers an extremely compact structure and a virtually unobstructed flow path. This true full-bore design is particularly suitable for conveying media prone to sedimentation, such as slurries, muds, and powders.

Sealing Method: Early knife gate valves were mostly unidirectional, relying on media pressure to push a resilient seat (such as polyurethane or rubber) against the gate to achieve a seal. Modern technology has also developed bidirectional sealing knife gate valves, but their core design is still focused on handling shutoff issues under harsh operating conditions, rather than providing high-precision sealing.

The differences in their structures directly lead to distinct application scenarios.

Ordinary Gate Valve:

Applicable Media: Clean liquids and gases, such as water, steam, oil, and natural gas. They should never be used with media containing solid particles or viscous media, as this can easily cause wear and scratches on the valve seat and gate, leading to seal failure and even inability to open or close.

Performance Characteristics: Excellent sealing performance, high leakage rating (can reach zero leakage), low flow resistance, and relatively high operating torque. Suitable for high pressure, high temperature, and critical shutoff conditions.

Knife Gate Valve:

Applicable Media: Designed specifically for harsh media, such as papermaking pulp, mineral slurry, sewage, mud, powders, particulate matter, and viscous liquids. Performance Characteristics: The ultra-thin, knife-edge-shaped gate disc easily cuts off the media flow and prevents clogging. The full-bore design minimizes pressure loss and resists material accumulation. The short design is lightweight and requires minimal installation space. However, its sealing performance is generally inferior to that of conventional gate valves, especially under low pressure or vacuum conditions.

In summary, while both knife gate valves and conventional gate valves belong to the same gate valve category, they are designed to solve different problems. When selecting a valve, the primary consideration is to understand the media characteristics. If the media is clean and requires high sealing performance, choose a conventional gate valve. If the media contains particles, fibers, or is viscous and prone to clogging, a knife gate valve is a better, or even the only, choice.