What is Lug type butterfly valve?

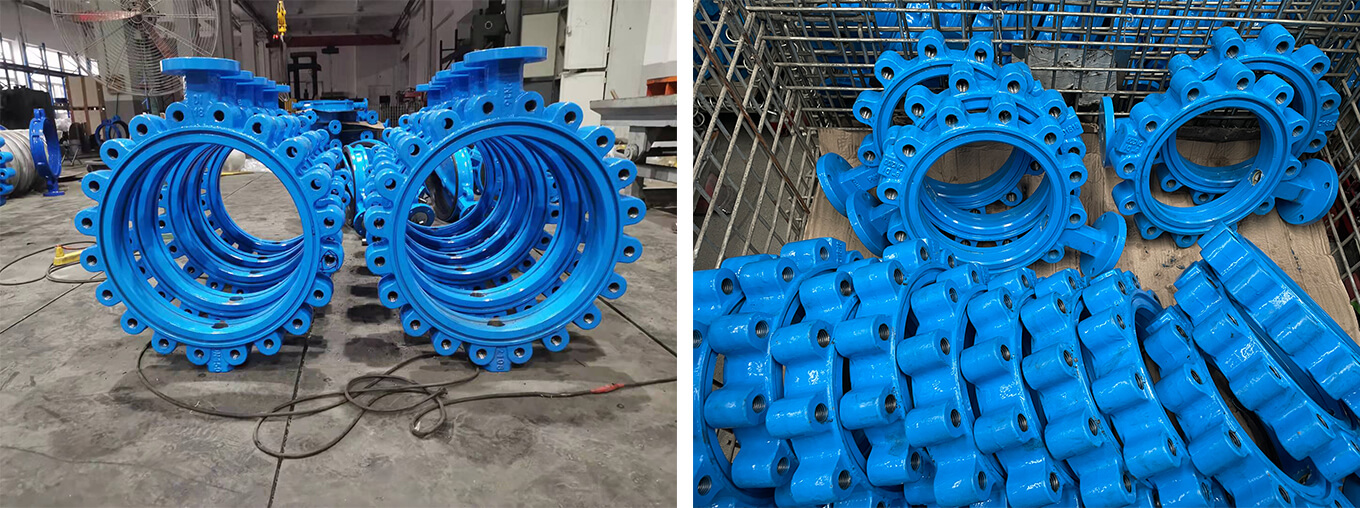

Introduction of lug type butterfly valve:

Lug type butterfly valve drive mode: generally manual, worm gear, pneumatic, electric.

Connection mode: flange, butt-clamp.

Structure: single eccentric, midline, double eccentric, triple eccentric.

The seal structure is generally: soft seal, hard seal, pressure range PN0.1-10Mpa, nominal diameter DN40 ~ 2000mm, the material is generally: cast steel, stainless steel, cast iron, etc. As the use of the valve is very wide, the same kind of valve in different occasions and working conditions have different collocation.

The butterfly plate of the counter clamp lug butterfly valve is installed in the diameter direction of the pipeline. In the cylindrical channel of the butterfly valve body, the disc-shaped butterfly plate rotates around the axis, and the rotation angle is between 0° and 90°, and when it rotates to 90°, the valve is fully open.

Structural characteristics of the butt-clamp butterfly valve:

The biggest structural feature of the clamp-on butterfly valve is that the structure is particularly simple, small in size and light in weight, and consists of only a few parts. The reason why the clamp-on butterfly valve has these quality features is that the clamp-on butterfly valve is connected between two pipe flanges with double-headed bolts; at the same time, the clamp-on butterfly valve has good fluid control characteristics for reason 1: it only needs to be rotated 90° during operation to fast opening and closing, the operation is very simple, reason 2: when the butterfly valve is in the fully open position, the thickness of the butterfly plate is the only resistance when the medium flows through the valve body, so the pressure drop generated through the valve is very small.

What is Lug type butterfly valve?

Applicable working conditions of butterfly valve:

The butterfly valve is widely used for flow regulation. As the pressure loss of butterfly valve in the pipeline is large, about three times that of the gate valve. Therefore, when selecting a butterfly valve, full consideration should be given to the pipeline system affected by the pressure loss, and consideration should also be given to the sturdiness of the butterfly plate to withstand the pressure of the pipeline medium when closed, as well as the limit of the working temperature that the resilient seat material can withstand at high temperatures.

The structure length and overall height of the butterfly valve is relatively small, opening and closing speed blocks, with good fluid control characteristics, and its architecture principle is most suitable for making large diameter valves. When butterfly valves are required for flow control use, the most important thing is to choose the correct size and type of butterfly valve so that he can work more effectively.

Usually, in throttling, regulating control and slurry media, short structure length and fast opening and closing speed are required. For low pressure shut-off, butterfly valves are recommended.

Butterfly valves are generally widely used in industry, such as petroleum, gas, chemical, water treatment, etc., while butterfly valves are also used in the cold water system of thermal power stations.

Used for gas pipeline in sulfuric acid industry: furnace blower inlet and outlet, relay fan inlet and outlet, electric mist elimination series and coupling valve, S02 main blower inlet and outlet, converter adjustment, preheater inlet and outlet, etc. to adjust and cut off the gas volume used.

Because the butterfly valve has good sealing performance, light operation, vice corrosion, high temperature resistance, easy operation, flexibility, safe and reliable use, so the butterfly valve is also widely used in the sulfur burning, conversion, dry suction section in the sulfur acid system.

Because of the high quality property of the lug type butterfly valve itself, it has better stability when connected with pipeline, so the lug type butterfly valve is also widely used in various working conditions, such as chemical industry, smelting, medicine, food, etc. It can also pass various gases (steam, gas), various acidic media (seawater, nitric acid, etc.), and be used as regulating and intercepting device on the pipeline.

Butterfly valve in the process of use precautions:

①Valves should be stored in a dry, ventilated room, the valve channel should be blocked at both ends.

②Valves stored for a long time should be regularly inspected and cleared of dirt. Special attention should be paid to the cleaning of the sealing surface to prevent damage to the sealing surface.

③ Before installation should be carefully checked whether the valve markings are equal to the use requirements.

④The valve channel and sealing surface should be checked before installation, and if there is dirt, it should be wiped clean with a clean cloth.

⑤ Check whether the packing is pressed before installation, and should ensure the sealing of the packing, and at the same time should not hinder the rotation of the valve stem.

⑥The tightening force of the connecting bolts should be uniform and appropriate when installing.

⑦ Butterfly valve can be installed horizontally and vertically on the pipeline, and the installation position should ensure the use of maintenance and replacement convenience.

⑧ manual valve in the opening or closing operation, should use the handle to open and close, shall not borrow auxiliary bar or other tools.

⑨ valve use should be regularly inspected, check the sealing surface for wear and gasket packing. If the damage fails, should be repaired or replaced in a timely manner.