Introduction of knife gate valve:

In the realm of industrial valves, where precision, reliability, and efficiency reign supreme, the knife gate valve emerges as a stalwart champion. Renowned for its unique design and functionality, the knife gate valve stands out as a vital component in various industries, from wastewater treatment plants to mining operations and beyond.

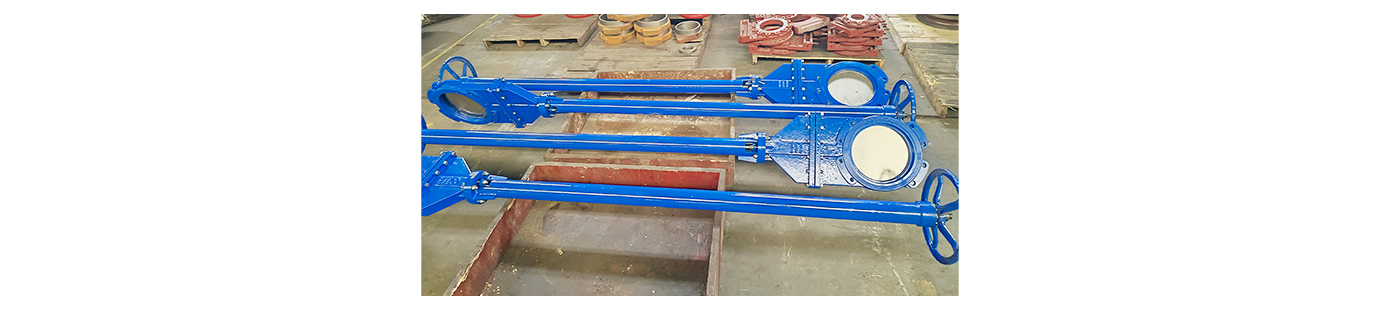

A knife gate valve, as the name suggests, employs a blade to control the flow of fluids. This blade, typically made of stainless steel or other durable materials, moves up and down to either permit or obstruct the passage of fluids through the valve. The simplicity and effectiveness of this mechanism make knife gate valves indispensable in applications where reliable shutoff is paramount.

Advantages of Knife Gate Valves:

Superior Shut-Off Performance:

Knife gate valves offer exceptional shut-off capabilities, effectively sealing off pipelines even in demanding conditions. Whether dealing with abrasive slurries or viscous fluids, the knife gate valve ensures minimal leakage, enhancing operational efficiency and safety.

Bi-Directional Flow Control:

Unlike some traditional valves, knife gate valves facilitate bi-directional flow control. This versatility allows for seamless operation in both directions, catering to diverse industrial processes with ease.

Minimal Maintenance Requirements:

Thanks to their robust design and streamlined construction, knife gate valves entail minimal maintenance. This translates to reduced downtime and lower maintenance costs, making them a cost-effective choice for industries worldwide.

Resilience to Abrasive Media:

One of the standout features of knife gate valves is their resilience to abrasive media. Whether handling slurry, pulp, or wastewater laden with solids, these valves excel in maintaining operational integrity over extended periods.

Compact Design:

Knife gate valves boast a compact design, making them ideal for installations in constrained spaces. This space-saving attribute ensures optimal utilization of available infrastructure, enhancing overall system efficiency.

Rapid Opening and Closing:

With their swift opening and closing times, knife gate valves facilitate efficient flow control, particularly in processes requiring quick response times. This agility enhances productivity and responsiveness across various industrial applications.

Compatibility with Harsh Environments:

Knife gate valves exhibit exceptional resilience to harsh environments, including corrosive chemicals and extreme temperatures. This durability ensures sustained performance even in the most demanding operating conditions.

Versatility Across Industries:

From mining and wastewater treatment to power generation and beyond, knife gate valves find application across a wide spectrum of industries. Their adaptability and reliability make them a preferred choice for diverse industrial processes.

Main Material Types and Applicability of Knife Gate Valve:

Stainless Steel:

Stainless steel knife gate valves offer excellent corrosion resistance, making them suitable for handling corrosive fluids such as acids and alkalis. They are commonly used in chemical processing, wastewater treatment, and marine applications.

Cast Iron:

Cast iron knife gate valves are renowned for their durability and affordability. They find widespread use in applications involving sewage, slurries, and other abrasive media, particularly in municipal wastewater treatment plants and mining operations.

Carbon Steel:

Carbon steel knife gate valves combine strength and corrosion resistance, making them well-suited for applications involving high-pressure fluids and elevated temperatures. They are commonly employed in power generation, oil and gas, and pulp and paper industries.

PVC:

PVC knife gate valves are preferred for applications requiring resistance to chemical corrosion and abrasion. They are widely used in water treatment, irrigation, and chemical processing industries, where compatibility with corrosive fluids is essential.

In conclusion, knife gate valves epitomize efficiency, reliability, and versatility in flow control applications. With their robust construction, superior performance, and compatibility with diverse operating conditions, these valves continue to play a pivotal role in driving industrial processes forward. From safeguarding pipelines against abrasive media to facilitating seamless flow control in critical operations, the knife gate valve stands as a testament to engineering ingenuity and innovation.