The sealing surface is the most critical working surface of the valve. The quality of the sealing surface directly affects the service life of the valve. The material of the sealing surface is an important factor in ensuring the quality of the sealing surface.

①Corrosion resistance.

“Corrosion” is the process in which the surface of the sealing surface is damaged under the action of the medium. If the surface is damaged in this way, sealing cannot be guaranteed, so the sealing surface material must be corrosion-resistant. The corrosion resistance of materials mainly depends on the properties of the material and its chemical stability.

②Anti-scratch.

“Scuffing” refers to damage to materials caused by friction during the relative movement of the sealing surfaces. This damage will inevitably cause damage to the sealing surface. Therefore, the sealing surface material must have good scratch resistance, especially for gate valves. The scratch resistance of a material is often determined by the internal properties of the material.

③Erosion resistance.

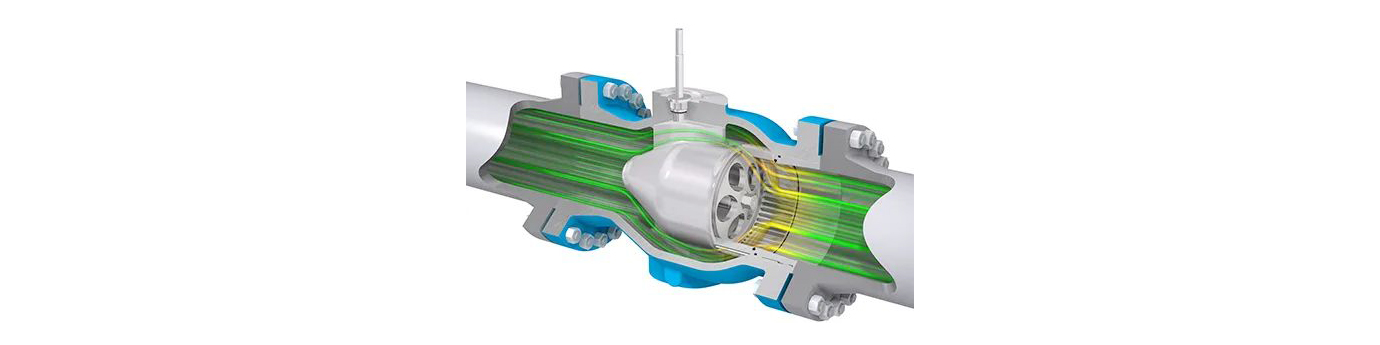

“Erosion” is the process in which the sealing surface is destroyed when the medium flows through the sealing surface at high speed. This kind of damage is more obvious in throttle valves and safety valves used in high-temperature and high-pressure steam media, which has a great impact on sealing damage. Therefore, erosion resistance is also one of the important requirements for sealing surface materials.

④ It should have a certain hardness, and the hardness will drop significantly under the specified working temperature.

⑤ The linear expansion coefficients of the sealing surface and the body material should be similar, which is more important for the structure of the inlaid sealing ring to avoid additional stress and loosening under high temperatures.

⑥ When used under high temperature conditions, it must have sufficient resistance to oxidation, thermal fatigue, thermal cycle and other issues.

Under the current circumstances, it is difficult to find sealing surface materials that fully meet the above requirements. We can only focus on meeting certain requirements based on different valve types and uses. For example, valves used in high-speed media should pay special attention to the erosion resistance requirements of the sealing surface; and when the medium contains solid impurities, sealing surface materials with higher hardness should be selected.