In engineering projects, butterfly valves are indispensable key components in fluid control systems. From water treatment and municipal engineering to power and chemical projects, the performance of butterfly valves directly affects system safety, operational efficiency, and cost control. For procurement personnel and engineers, choosing the right butterfly valve and a reliable supplier is crucial for the successful implementation of the project. This article will provide a comprehensive reference for engineering project procurement customers from four aspects: butterfly valve selection, applicable projects, supplier selection, and procurement suggestions, while naturally incorporating the advantages of WEIZIDOM butterfly valves.

Engineering project butterfly valves are valves specifically designed for industrial and large-scale infrastructure projects, possessing the following characteristics:

Excellent pressure and corrosion resistance: capable of withstanding high pressure, high temperature, or corrosive media

Flexible operation: supports manual, electric, pneumatic, or gear drive

Low maintenance costs: simple structure, easy to maintain

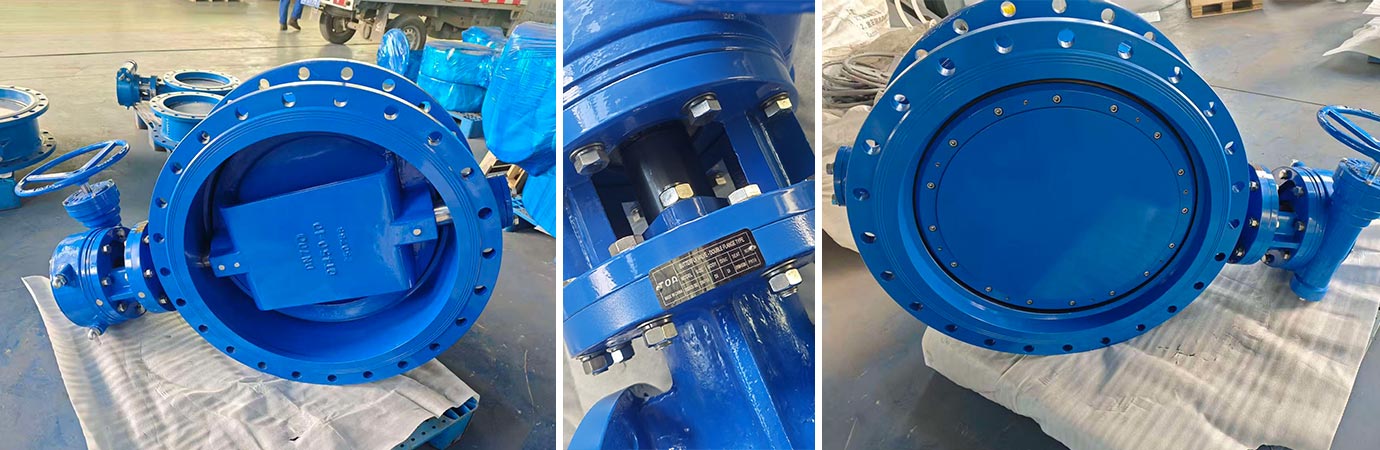

Soft-seated butterfly valves: The sealing ring is made of rubber, suitable for general media such as clean water and sewage.

Hard-seated butterfly valves: The sealing surface is made of metal or high-performance materials, suitable for high pressure, high temperature, and corrosive media.

Flanged/Wafer type butterfly valves: Easy to install, adaptable to different pipe diameters and pipeline layouts.

Multiple material options (cast iron, carbon steel, stainless steel)

High-performance sealing materials, corrosion-resistant, wear-resistant, and long service life

Can be equipped with various actuators such as manual, electric, and pneumatic, supporting automation systems

When purchasing butterfly valves, procurement customers need to select products suitable for the working conditions based on the project type. Common engineering projects include:

Water treatment projects: municipal water supply and drainage, sewage treatment plants, pumping station systems

Power engineering: cooling water systems, steam pipelines, circulating water control

Chemical and petrochemical engineering: transportation of corrosive chemical media, hot water and steam pipelines

Building and fire protection engineering: air conditioning systems, fire water pipes, pressure control systems

Procurement Tip: Different projects have different requirements for valve materials, sealing performance, and actuators. Working conditions must be clearly defined in advance.

1. Analyzing Operating Conditions

Medium type: Water, steam, oil, or corrosive chemical media

Pressure rating: High-pressure systems require valves with high pressure resistance

Temperature range: High or low temperature conditions require appropriate sealing materials

Pipe diameter and flow rate: Ensure the butterfly valve diameter matches the pipe and meets flow control requirements

2. Material and Seal Selection

Valve body material: Cast iron, carbon steel, stainless steel

Sealing material: Rubber, PTFE, metal seal

Purchasing suggestion: Choose high-performance materials that have undergone corrosion and wear resistance testing (such as WEIZIDOM butterfly valves) to reduce maintenance costs and failure risks

3. Actuator Selection

Manual, gear drive, electric, or pneumatic

For projects requiring high levels of automation control, choose electric or pneumatic butterfly valves that can be remotely operated

4. Brand and Performance Evaluation

Does the supplier have certifications (ISO9001, CE, etc.)?

Does the product provide a complete factory inspection report and warranty?

Are there successful engineering case studies to verify performance?

When purchasing butterfly valves for engineering projects, choosing a reliable supplier is more important than simply comparing prices. Core evaluation criteria include:

✔Qualifications and Certifications

✔ISO9001 quality system certification, CE certification, and industry qualifications

✔Brand reputation and historical project experience

✔Product Quality and Performance

✔Design standards, pressure rating, sealing performance

✔Complete factory inspection reports and clear warranty commitments

✔Supply Capacity and Service

✔Does the production capacity meet the project’s bulk requirements?

✔Stable delivery cycle and timely after-sales service response

✔Industry Experience and Successful Cases

✔Practical application experience in water treatment, power, chemical, and construction engineering projects

✔Good customer reputation and comprehensive technical support

Purchasing Tip: Choosing a supplier with mature engineering case studies and strong technical capabilities can significantly reduce project risks. WEIZIDOM butterfly valves have extensive application experience in various large-scale engineering projects, providing reliable assurance for purchasing customers.

For customers purchasing butterfly valves for engineering projects, scientific selection and supplier choice are crucial:

Clearly define operating conditions and select appropriate materials, seals, and actuators.

Prioritize suppliers with certifications, reliable quality, timely delivery, and comprehensive after-sales service.

Consider brand reputation and technical service capabilities to ensure the smooth operation of the project.

Choosing WEIZIDOM butterfly valves means choosing high-performance butterfly valves and a reliable supplier, providing safe, stable, and economical solutions for engineering projects.

Related products: Butterfly valves for engineering projects, reliable butterfly valve suppliers, industrial butterfly valve procurement, WEIZIDOM butterfly valves, water treatment butterfly valves, power engineering valves, recommended manufacturers of chemical corrosion-resistant butterfly valves