In modern fire protection systems, valves are one of the core components that ensure the normal operation of the entire pipeline network. With the continuous expansion of urban infrastructure and building volume, fire water supply systems are placing higher demands on valve performance, durability, and convenience. Among the many valve types, butterfly valves are widely used in fire water supply systems and related supporting facilities due to their compact structure, flexible opening and closing, and stable sealing performance. This article will begin with a basic introduction and advantages of butterfly valves, then delve into the types of fire butterfly valves and further explain how to select the appropriate fire butterfly valve.

A butterfly valve is a simple rotary regulating and shut-off valve. Its core design features a disc-shaped disc mounted within a cylindrical valve body, rotating about its own axis. By rotating the valve stem, the disc rotates 90 degrees from a position completely parallel to the water flow (fully open) to a position completely perpendicular to the water flow (fully closed), thereby controlling the flow and flow.

1. Compact Structure and Small Space Occupancy: Butterfly valves are short and low-profile, making them crucial for space-constrained fire pump rooms, pipe shafts, and suspended ceilings. They effectively optimize layout and save building space.

2. Fast Opening and Closing, Easy Operation: Fully opening or closing is achieved by simply rotating the handle or actuator 90 degrees, offering extremely fast response. Whether manually or with a worm gear drive, operating torque is low, facilitating quick and effortless operation in emergency situations.

3. Low Fluid Resistance, Energy-Saving and Highly Efficient: When the butterfly valve is fully open, the thickness of the disc is the only source of resistance, minimizing obstruction to the fluid. This significantly reduces head loss in the piping system, ensuring adequate pressure and flow at fire hydrants and sprinkler outlets.

4. Excellent Sealing Performance, Safety and Reliability: Modern firefighting butterfly valves generally utilize rubber or polymer elastic materials for their seat seals. When the valve is closed, the butterfly disc squeezes the resilient valve seat, achieving a bidirectional, zero-leakage seal, effectively preventing system leaks and maintaining pipeline pressure.

5. Easy Maintenance and High Cost-Effectiveness: Due to its simple structure and few moving parts, it has a low failure rate, making routine maintenance and replacement of wearing parts such as seals very convenient. Furthermore, its relatively low manufacturing cost makes it highly economical and practical.

To adapt to different installation environments, operating requirements, and system pressures, fire butterfly valves have evolved into various types, primarily categorized by their actuation and connection methods.

Handle Butterfly Valve: The valve stem is directly connected to a lever-type handle. This has the simplest structure, the most economical price, and offers intuitive status indication (open when the handle is parallel to the pipe, closed when perpendicular). It is commonly used in small-diameter pipe sections (typically under DN150) that require frequent manual operation, such as pump test pipes and end-of-pipe testing devices.

Worm Gear Butterfly Valve: The valve stem is driven by a worm gear reduction mechanism. Their biggest advantage is labor-saving operation and the ability to deliver substantial torque. They are suitable for large-diameter (DN150 and above) or high-pressure main pipes. Although their opening and closing speeds are slightly slower than handle-type valves, they offer greater stability and precision, making them the most common type for fire pump outlet pipes and main pipes.

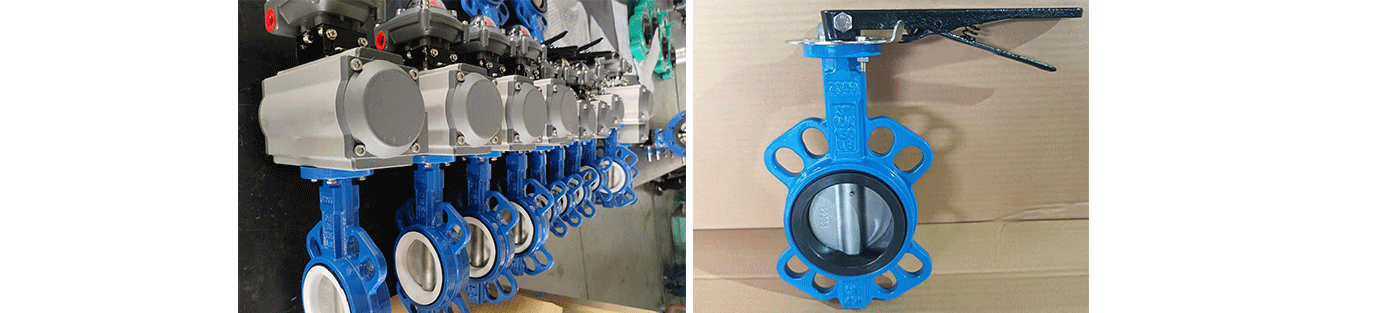

Electric/Pneumatic Butterfly Valves: These valves are connected to electric or pneumatic actuators for remote automatic control. They are often used in special applications requiring linkage with automatic fire alarm systems or in inaccessible installation locations, such as high-level water tank inlet control in high-rise buildings.

Wafer-Type Butterfly Valves: The valve body has no flanges and is “clamped” between two pipe flanges using long bolts. Their advantages include the shortest length, lightest weight, and lowest cost. Their disadvantage is that disassembly requires completely loosening the bolts on both pipe flanges.

Flange-Type Butterfly Valves: The valve has built-in flanges on both ends and connects directly to the pipe flanges with bolts. They offer the most stable and reliable installation, strong pressure-bearing capacity, and ease of individual disassembly and maintenance. However, they are relatively heavy and costly, making them the preferred connection method for fire main pipes.

Grooved (Clamp) Butterfly Valve: The valve body is grooved and connected using a dedicated rubber seal and clamp. Its greatest advantage is extremely fast installation, requiring no welding or threading. It is particularly suitable for rapid construction, renovation, and expansion of fire protection projects, and has become increasingly popular in recent years.

In fire protection systems, choosing the right butterfly valve not only affects system reliability but also directly impacts efficient water supply in the event of a fire. The following factors can serve as a guide for selection:

1. Identify the application scenario and functional requirements.

For main pipelines, flanged butterfly valves are recommended to ensure connection strength and long-term reliability.

If remote monitoring or automated control is required, butterfly valves with signaling devices or electric/pneumatic butterfly valves should be selected.

2. Select based on pipe diameter and pressure rating.

For small and medium-diameter pipes, wafer-type butterfly valves are economical and practical.

For large-diameter or high-pressure pipes, flanged or turbine-driven butterfly valves are recommended to improve operational and sealing reliability.

3. Pay attention to fire certifications and standards.

Fire butterfly valves must comply with local or international fire standards, such as UL, FM, and CCCf.

Choosing certified products not only improves system safety but also ensures smooth fire inspections.

4. Focus on materials and sealing performance.

Valve bodies are commonly made of ductile iron or carbon steel, which offer excellent strength and pressure resistance.

Valve seats are often made of water-resistant rubber such as EPDM or NBR to ensure a long-term seal.

5. Consider cost-effectiveness and ease of maintenance.

While meeting performance and safety requirements, consider both procurement costs and ongoing maintenance to avoid compromising system reliability by excessively pursuing low prices.

As a key valve in fire protection systems, butterfly valves are widely used in fire protection pipe networks due to their structural advantages, ease of operation, and reliable sealing. As a professional industrial valve supplier, WEIZIDOM is committed to providing customers with high-quality fire butterfly valves and system solutions. We strictly adhere to international standards to ensure the reliability and durability of each valve. Through continuous innovation and service improvement, WEIZIDOM contributes to global fire safety and becomes a trustworthy partner.