Due to their unique disc-type opening and closing structure, low pressure drop, and economical performance, butterfly valves are one of the most widely used valve types in industrial piping systems. Their core function is to quickly shut off and precisely throttle fluid flow by rotating the valve stem to drive the disc, demonstrating their significant advantages in large-diameter, low-pressure pipelines. The following is an in-depth look at their key industry applications:

Power Industry

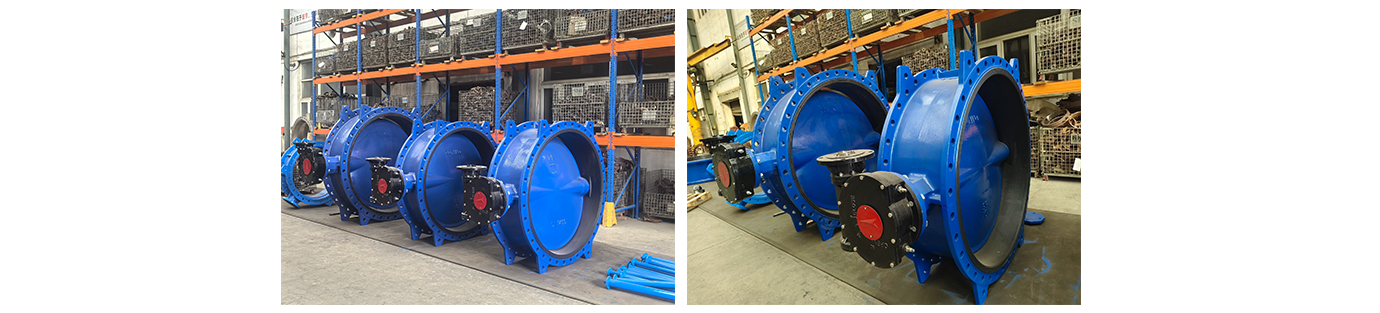

Thermal/Nuclear Power Plants: Used in circulating cooling water systems, boiler feed water, steam drains, and flue gas desulfurization pipelines to provide medium flow control and flow regulation. Large-diameter butterfly valves are commonly used in cooling water inlet mains.

Water Treatment Plants: They perform critical opening, closing, and regulating functions in the inlet and outlet pipes of aeration tanks and sedimentation tanks in municipal water supply and drainage pumping stations and sewage treatment plants. Their low pressure drop reduces system energy consumption.

Chemical and Petrochemical Industries

Widely used in various corrosive media (acids and alkalis), oil, and slurry pipelines. The self-cleaning properties of the disc during rotation make it suitable for use in conditions involving solid particles or powders.

Process Pipeline Regulation: In reactor feed and product delivery pipelines, sensitive flow control is achieved by adjusting the opening angle (15° to 70°).

Metallurgy and Mining Industries

Applied in blast furnace cooling systems, dust removal pipelines, slurry conveying lines in mineral processing plants, and tailings treatment systems. Metal-sealed butterfly valves can withstand high-temperature, dusty environments and particle erosion.

Municipal Engineering

Water Supply Networks: As key shutoff valves in main pipelines and control valves in pump stations, rubber-sealed butterfly valves dominate water systems due to their excellent sealing properties. Drainage and Flood Control: Widely used in stormwater pumping stations, sewage lift stations, and sewage treatment plants, the large-diameter design meets high flow demands.

Heating, Ventilation, and Air Conditioning (HVAC) Systems: Regulates flow and distribution in chilled water and cooling water circulation lines to maintain a balanced heating/cooling system for the district. Its compact structure and lightweight design facilitate installation in building manholes.

Environmental Protection and Waste Gas Treatment

Special Fluid Control: Can handle special fluids such as liquid metals and radioactive media (requiring special materials and certification).

Multi standard EPDM sealed butterfly valve

Single flange butterfly valve

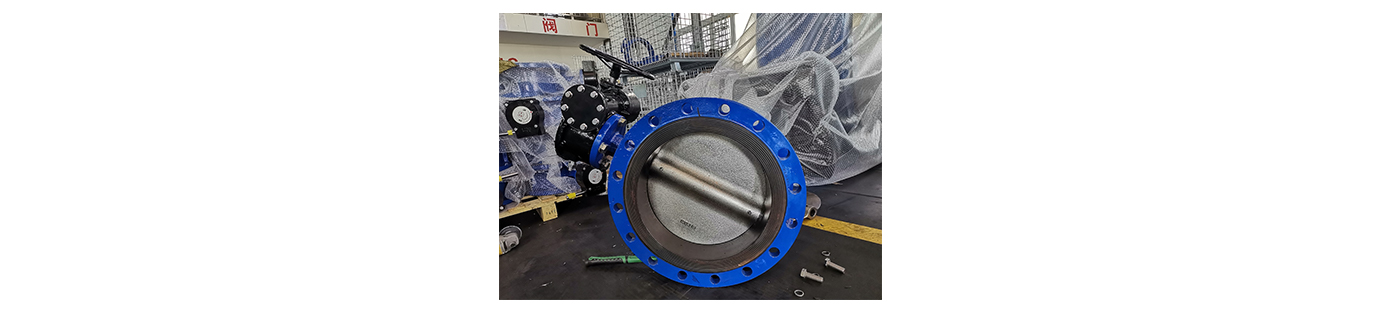

Flange butterfly valve

Lug butterfly valve

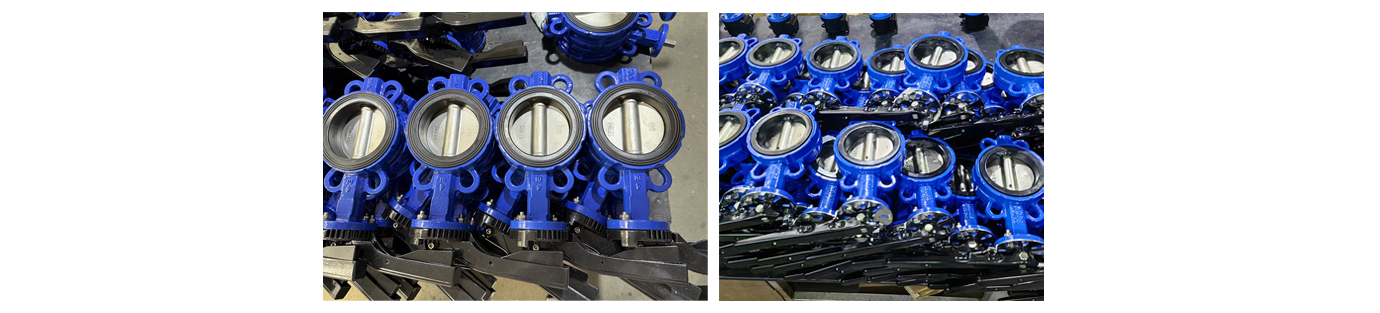

Wafer butterfly valve with handle

Worm gear operated butterfly valve

Wafer lined fluorine butterfly valve

Stainless steel wafer butterfly valve

Stainless steel flanged butterfly valve

Three eccentric flange butterfly valve

Pneumatic flanged butterfly valve

Pneumatic wafer butterfly valve

Triple eccentric butterfly valve wafer type

Wafer butterfly valve ULC approved

Inflatable seat butterfly valve

Grooved end butterfly valve

Electric soft seal butterfly valve

Flange fluorine lined butterfly valve

Handle aluminum butterfly valve

Worm Gear Aluminum Butterfly Valve

Full PTFE lined butterfly valve wafer type

One stem no-pin wafer butterfly valve

Multi standard aluminum stem butterfly valve

Stainless Steel wafer Butterfly Valve

Aluminium handle operated lug butterfly valve

Lever Operated Flange Butterfly Valve